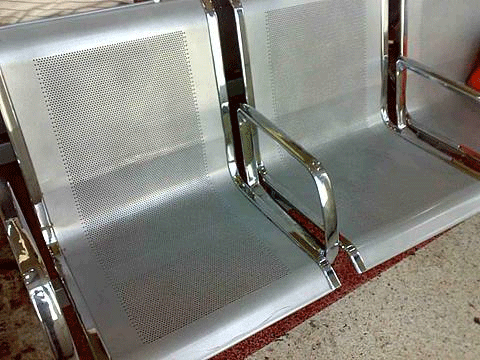

Round Hole - The Most Popular Perforated Sheet Patten

According to the latest surveys, most perforated sheets are produced with round holes. Why? Round roles are manufactured relatively easier with aesthetic effects. The circular die for punching sheet can last longer and easy to be manufactured which makes the round hole perforated sheet cheaper than any other perforated sheet with other hole patterns. Therefore, round hole pattern becomes the most popular shape.

Round hole perforated sheet offers the widest options of hole sizes, gauges, materials and sheet size for all types of applications. For example:

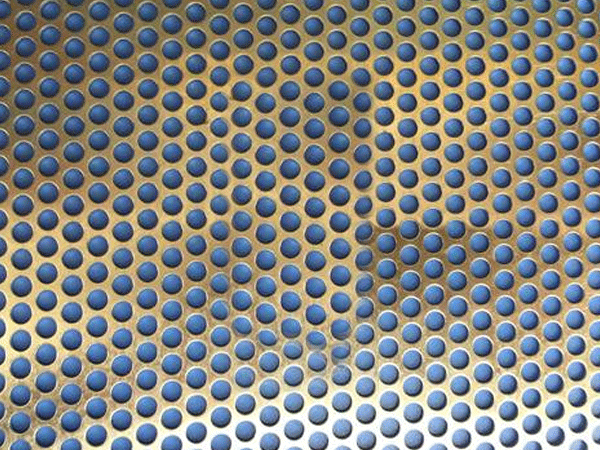

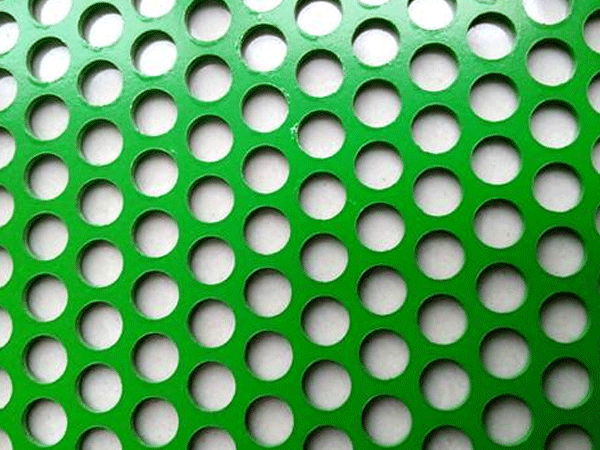

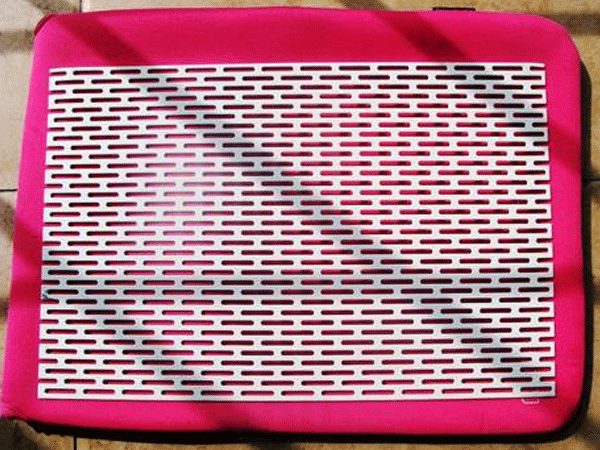

Round hole perforated sheet

- Cladding and ceiling panels.

- Sunshade and sunscreen.

- Filter to sieve seed, stone and other bulk materials.

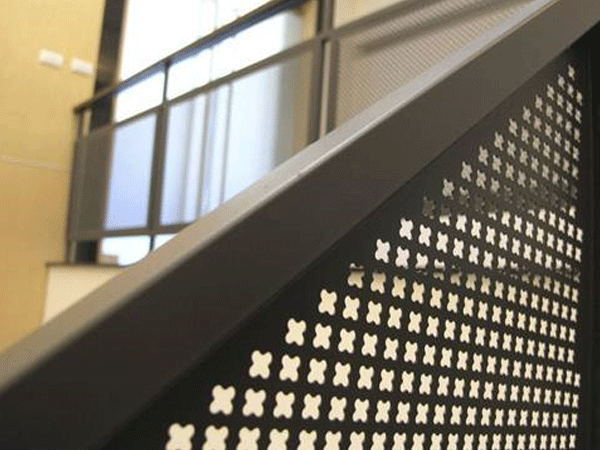

- Decorative banister.

- Protective fences of overpasses and machine equipments.

- Balcony and balustrade panels.

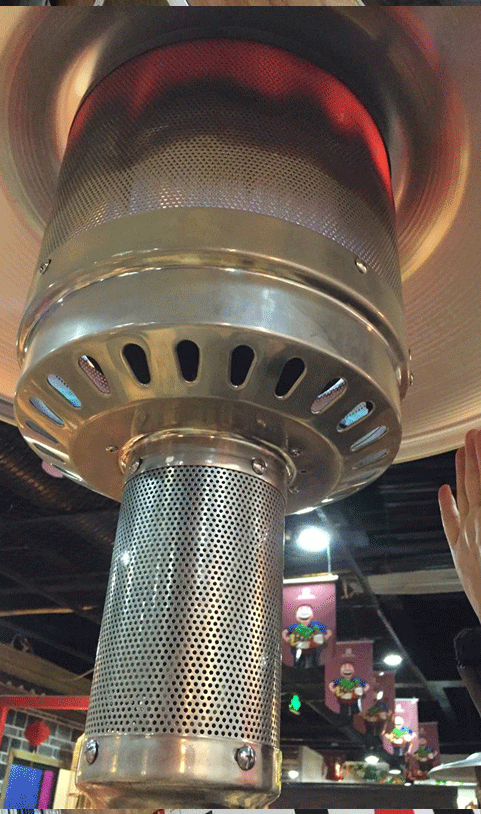

- Ventilation sheet, such as air condition grilles.

The perforated sunshades and claddings can provide privacy for the building occupants without any view obstruction. Meanwhile, it features control of interior climate to reduce the load of air condition and save energy to a large extent. Perforated fences and banister secure the safety of people and keep enclosed machines and other properties form damage.

RHPS-3: Round hole perforated sheet with holes 5.00 mm diameter, pitch 6.5 mm, perforated plate thickness 1.0 mm. Materials can be available in steel, stainless steel, aluminum and copper.

Round hole perforated sheet we supply:

Material:

We specializes in manufacturing round hole perforated sheets in various high quality materials including steel (mild steel or carbon steel, no painting, galvanized or PVC coated), stainless steel, aluminium, copper and brass or other materials as your request.

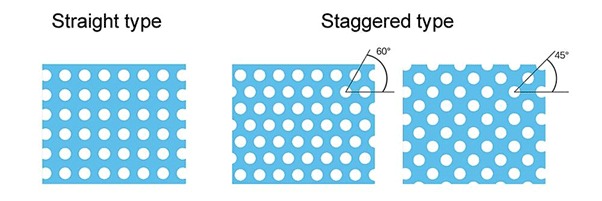

Hole pattern:

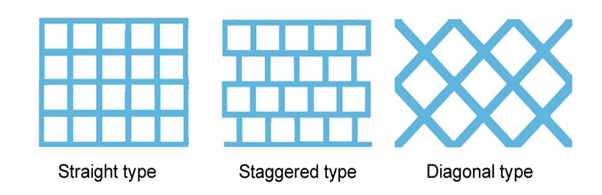

There are three ways of arrangements of round holes are adopted: straight type, 60° staggered type and 45° staggered type as shown in the following picture:

Thickness:

0.2 mm to 6 mm or as client requirements.

| Perforated sheet specification – Round hole | ||||||||||||||||

| Description | Hole Size (mm) |

Pitch (mm) |

Open Rate | Sheet Thickness | ||||||||||||

| 0.4 mm |

0.5 mm |

0.8 mm |

1.0 mm |

1.2 mm |

1.5 mm |

2.0 mm |

2.5 mm |

3.0 mm |

4.0 mm |

5.0 mm |

6.0 mm |

|||||

| R0.8 T2 | 0.80 | 2.00 | 15% | * | * | * | ||||||||||

| R1 T2 | 1.00 | 2.00 | 23% | * | * | * | * | |||||||||

| R1.2 T2.25 | 1.20 | 2.25 | 26% | * | * | * | ||||||||||

| R1.2 T2.5 | 1.20 | 2.50 | 21% | * | * | * | ||||||||||

| R1.5 T2.75 | 1.50 | 2.75 | 27% | * | * | * | * | |||||||||

| R1.5 T3 | 1.50 | 3.00 | 23% | * | * | * | * | |||||||||

| R1.8 T3.5 | 1.80 | 3.50 | 24% | * | * | * | * | * | ||||||||

| R2 T3 | 2.00 | 3.00 | 40% | * | * | * | ||||||||||

| R2 T3.5 | 2.00 | 3.50 | 30% | * | * | * | * | |||||||||

| R2 T4 | 2.00 | 4.00 | 23% | * | * | * | * | * | ||||||||

| R2.5 T3.5 | 2.50 | 3.50 | 46% | * | * | * | * | * | * | |||||||

| R2.5 T4 | 2.50 | 4.00 | 35% | * | * | * | * | * | * | |||||||

| R2.5 T4.5 | 2.50 | 4.50 | 28% | * | * | * | * | * | * | |||||||

| R2.5 T5 | 2.50 | 5.00 | 23% | * | * | * | * | * | * | |||||||

| R3 T5 | 3.00 | 5.00 | 33% | * | * | * | * | * | * | * | ||||||

| R3 T6 | 3.00 | 6.00 | 23% | * | * | * | * | * | * | * | ||||||

| R3.5 T5 | 3.50 | 5.00 | 44% | * | * | * | * | * | ||||||||

| R4 T5 | 4.00 | 5.00 | 58% | * | * | * | ||||||||||

| R4 T6 | 4.00 | 6.00 | 40% | * | * | * | * | * | * | |||||||

| R4 T8 | 4.00 | 8.00 | 23% | * | * | * | * | * | * | * | * | |||||

| R5 T7 | 5.00 | 7.00 | 46% | * | * | * | * | * | * | |||||||

| R5 T8 | 5.00 | 8.00 | 35% | * | * | * | * | * | * | * | * | |||||

| R5 T10 | 5.00 | 10.00 | 23% | * | * | * | * | * | * | * | * | * | ||||

| R5 T2.5 | 5.00 | 25.00 | 4% | * | * | * | * | * | * | * | * | * | ||||

| R6 T8.5 | 6.00 | 8.50 | 45% | * | * | * | * | * | * | * | ||||||

| R6 T9 | 6.00 | 9.00 | 40% | * | * | * | * | * | * | * | * | |||||

| R6 T10 | 6.00 | 10.00 | 33% | * | * | * | * | * | * | * | * | * | * | |||

| R7 T10 | 7.00 | 10.00 | 44% | * | * | * | * | * | * | * | * | |||||

| R8 T8 | 8.00 | 11.00 | 48% | * | * | * | * | * | * | * | * | |||||

| R8 T8 | 8.00 | 12.00 | 40% | * | * | * | * | * | * | * | * | * | ||||

| R8 T8 | 8.00 | 15.00 | 26% | * | * | * | * | * | * | * | * | * | ||||

| R10 T13 | 10.00 | 13.00 | 54% | * | * | * | * | * | * | * | * | |||||

| R10 T14 | 10.00 | 14.00 | 46% | * | * | * | * | * | * | * | * | |||||

| R10 T15 | 10.00 | 15.00 | 40% | * | * | * | * | * | * | * | * | * | ||||

| R10 T18 | 10.00 | 18.00 | 28% | * | * | * | * | * | * | * | * | * | ||||

| R12 T16 | 12.00 | 16.00 | 51% | * | * | * | * | * | * | * | * | |||||

| R12 T17 | 12.00 | 17.00 | 45% | * | * | * | * | * | * | * | * | * | ||||

| R15 T20 | 15.00 | 20.00 | 51% | * | * | * | * | * | * | * | * | * | ||||

| R15 T21 | 15.00 | 21.00 | 46% | * | * | * | * | * | * | * | * | * | ||||

| R20 T25 | 20.00 | 25.00 | 58% | * | * | * | * | * | * | * | * | * | ||||

| R20 T27 | 20.00 | 27.00 | 50% | * | * | * | * | * | * | * | * | * | ||||

| R20 T28 | 20.00 | 28.00 | 46% | * | * | * | * | * | * | * | * | * | ||||

| R20 T30 | 20.00 | 30.00 | 40% | * | * | * | * | * | * | * | * | * | ||||

| R25 T34 | 25.00 | 34.00 | 49% | * | * | * | * | * | * | * | * | * | ||||

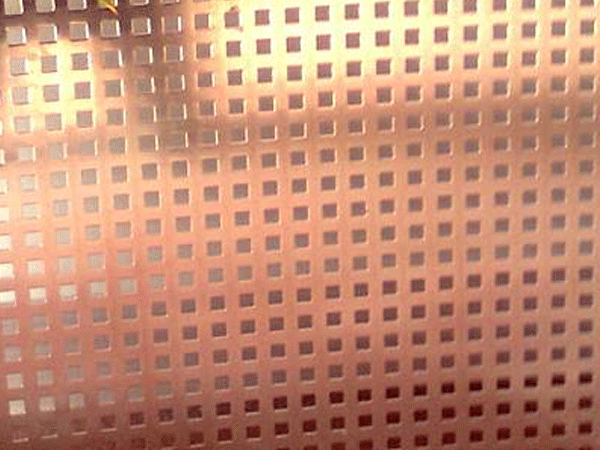

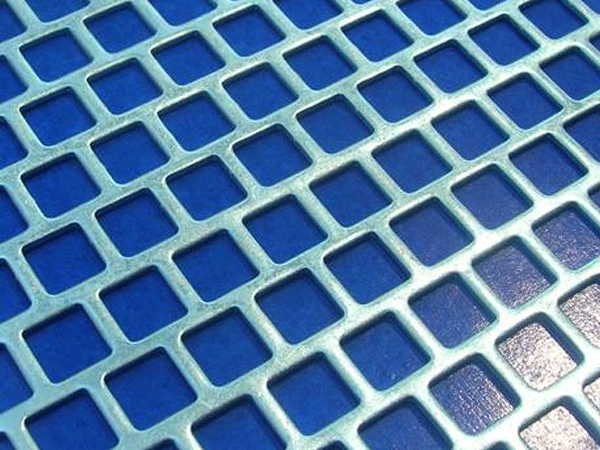

Square Hole - High Open Area for Ventilation

Square hole perforated sheet, punched by a square die, is known as an alternative to traditional round hole perforated sheet. With high open area, the sheet is often used as grilles especially speaker grilles to allow sound pass through easily while protecting the speaker from damage of vibration. Meanwhile, it also is used for shop fitting display offering excellent visibility.

The square hole perforated sheets prove to be multifunctional safety and ventilation sheets. For example:

- Machine guard.

- Air condition guard.

- Computer server chassis.

- Balconies and balustrades, etc.

They are considered to be versatile whether separation or decoration. For various applications, there are different sheets different materials, hole patterns, hole sizes and thickness to choose from.

High quality material:

We select the best materials for our square hole perforated sheets including:

- Steel (mile or carbon steel, no painted, galvanized or PVC coated).

- Stainless steel.

- Copper & brass.

- Custom materials are also available.

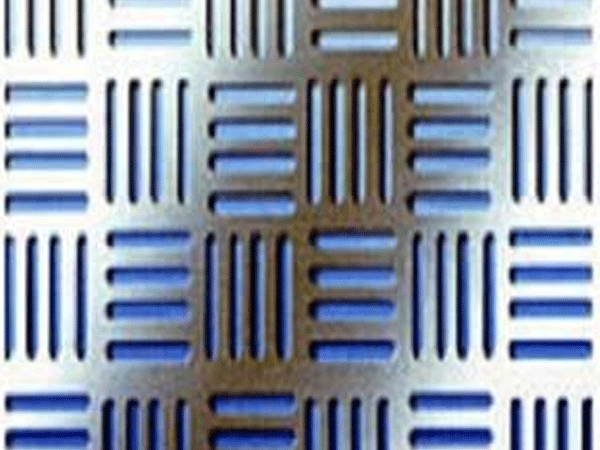

Various hole patterns:

Square hole perforated sheets can be supplied with straight, staggered and diagonal hole arrangements for your application. The most common and widest used type among them is the straight one.

Customizable hole sizes:

The hole size ranges from 20 mm to 500 mm or as per requirements

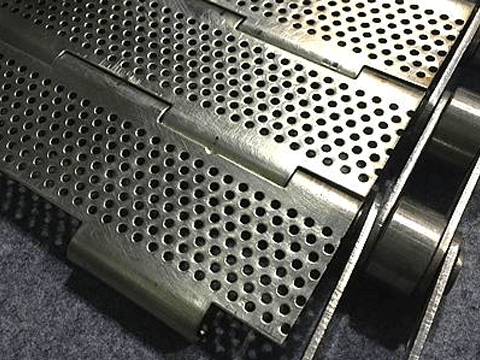

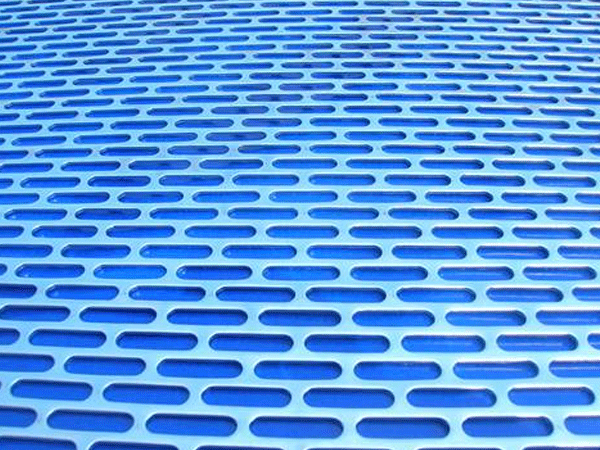

Slot Hole - Best Solution to Liquids and Solids Filtration

Slot hole perforated sheet is a versatile sheet or coil punched for elongated holes with round or square ends. Compared to similar perforated sheet with other hole pattern, this one proves to be the best solution to filtrate and sieve liquids and solids, such as water, wine, grain and seeds, etc.

Various applications:

- Act as sieves for grain & seeds cleaning and drying machine.

- Mill of flour and rice.

- Rope belt conveyors.

- Wall & ceiling panels.

- Cladding and sunshade.

- Fences and protective panels.

- Decorative applications, etc.

Optional material:

The materials most frequently used of the slot hole perforated sheet include mild, carbon steel, stainless steel, aluminium, copper, brass and any other material suitable for perforation.

Aesthetic hole patterns

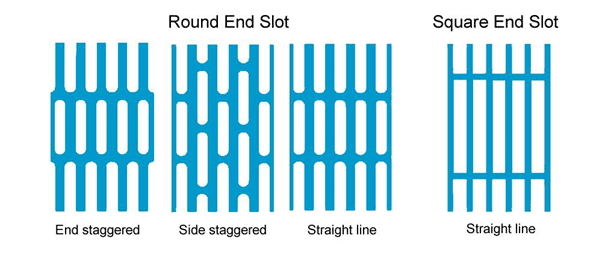

According to the desired application, there are many arrangements of slot holes including straight or staggered type as shown in the following picture:

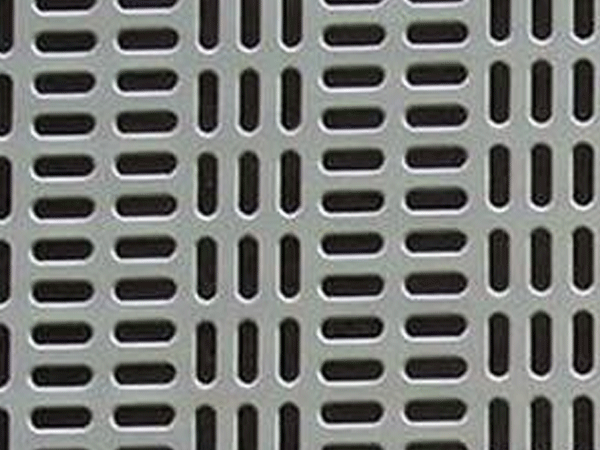

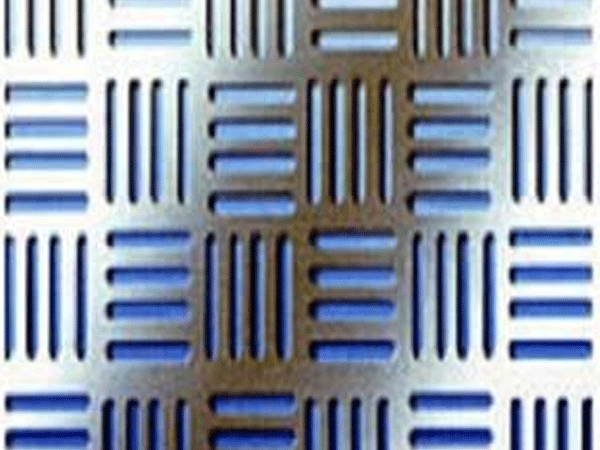

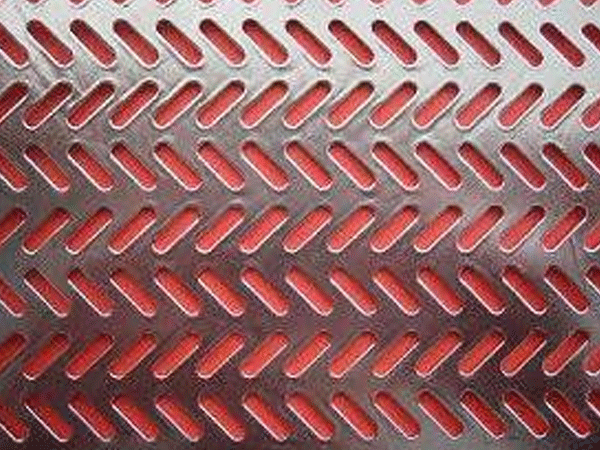

Meanwhile, to reach your desired aesthetic effect, we also supply other patterns of slot hole as your nominated, for example:

Hole size:

The slot hole should be punched with a width that at least the same size as the sheet thickness. When the slot width is the twice as much as the sheet thickness, the sheet performs best.

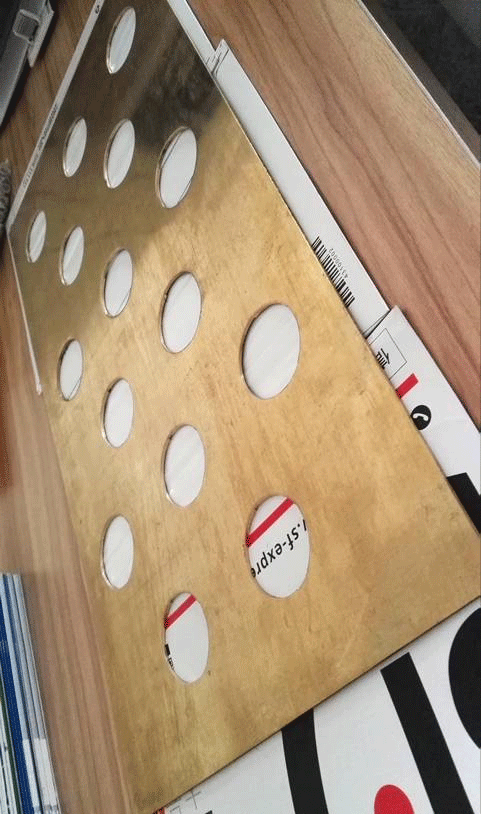

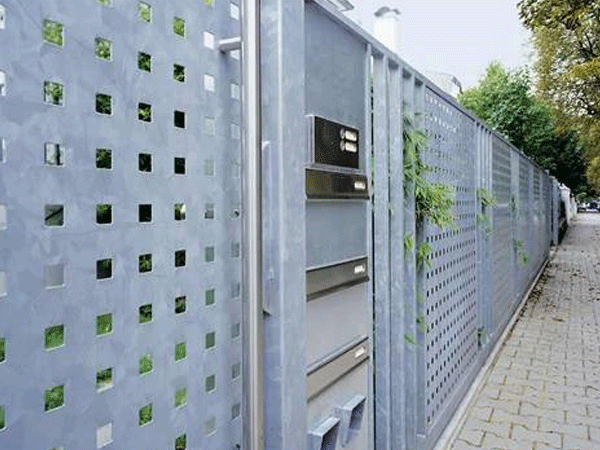

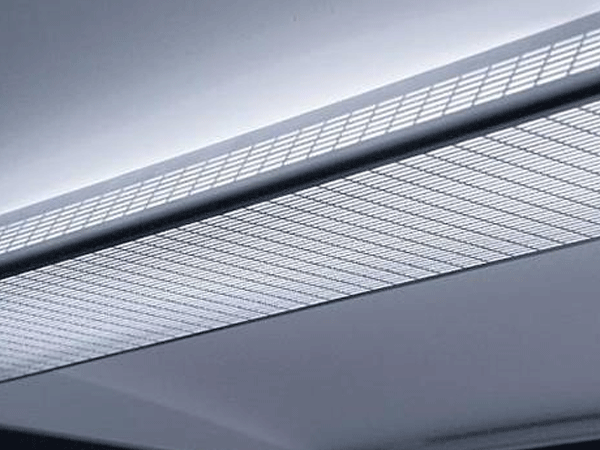

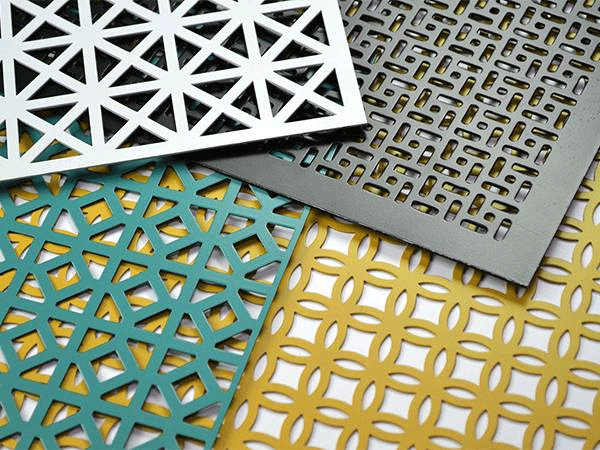

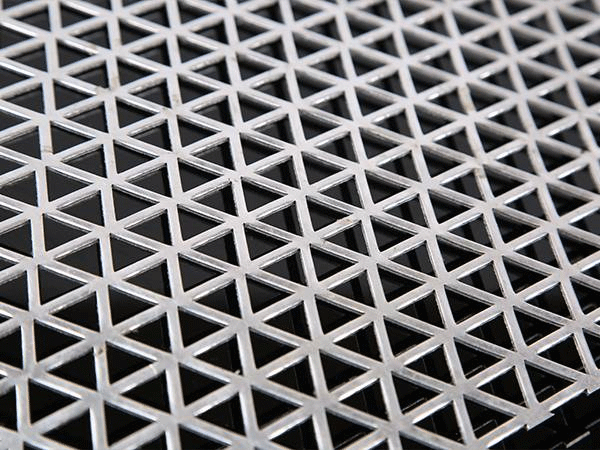

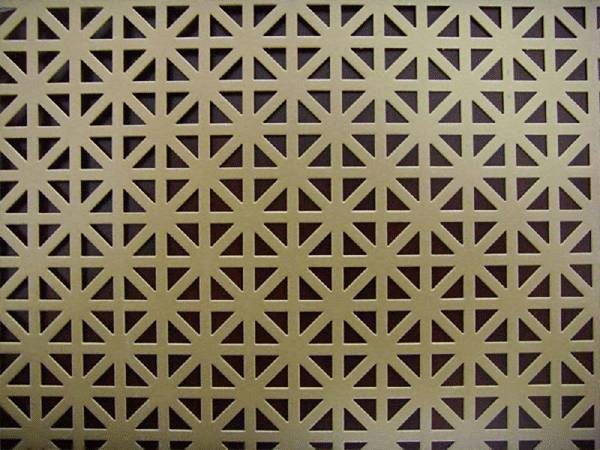

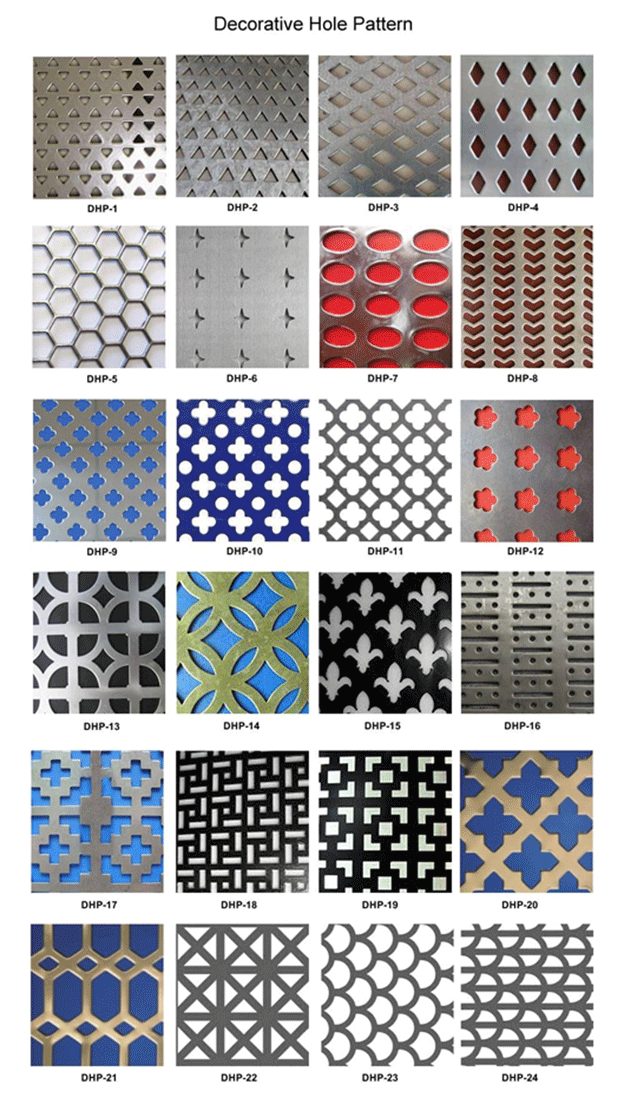

Decorations Various Hole Patterns for Interior or Exterior Decorations

Decorative perforated sheet, a choice of designs of enhancing appearance, is a sheet which is punched with stunning hole shapes. It is mainly used for architecture application where there is a need of aesthetic effect whether interior trim or exterior decoration.

Our company can supply customized hole patterns of decorative perforated sheets in different materials including mild steel, carbon steel, stainless steel, aluminium, brass, copper, etc. On request, decorative perforated sheets can be surface treated, for example:

- Galvanization

- Brushed finish

- Mirror finish

- Powder coating

- Anodizing

- High & brilliant polish

- Aged mill finish

- Reflective shine or dull mill finish

Meanwhile, a variety of decorative hole patterns are available, including diamond, hexagonal, flower, four-point star, oblong, and any other custom design you may desire can be created by our team.

Application

The decorative perforated sheet can be seen everywhere in our life. You will find that from the building facade, and security screen, to the interior ceiling & light design, cabinet in furniture, partition, decorative mesh for reception areas in hotel, restaurant, bar, and boutique, and even for car grille, the decorative perforated sheet exists in different holes.

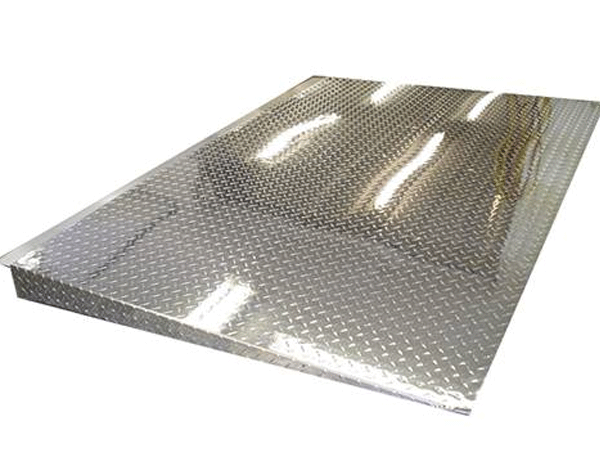

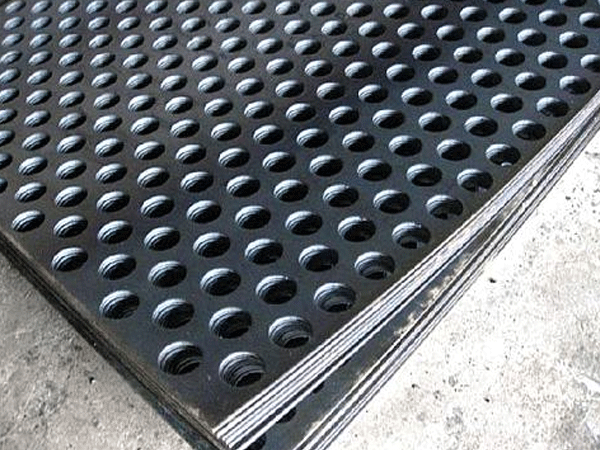

Embossed Sheet

Why You Need an Embossed Sheet?

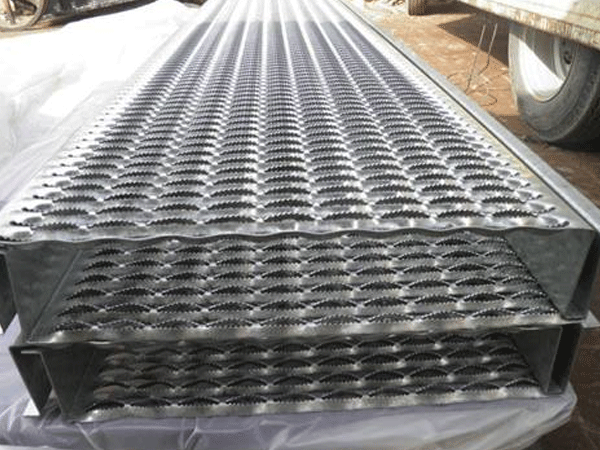

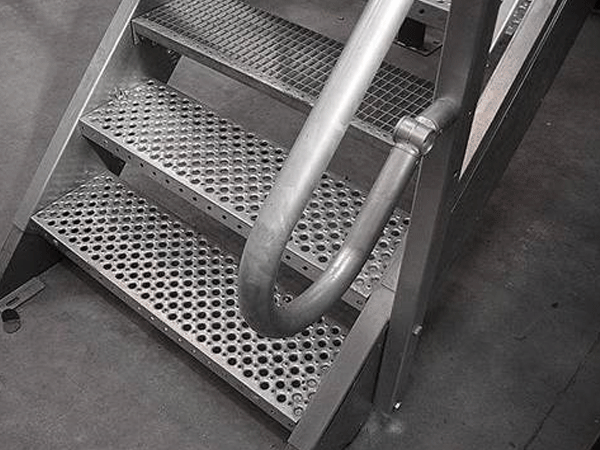

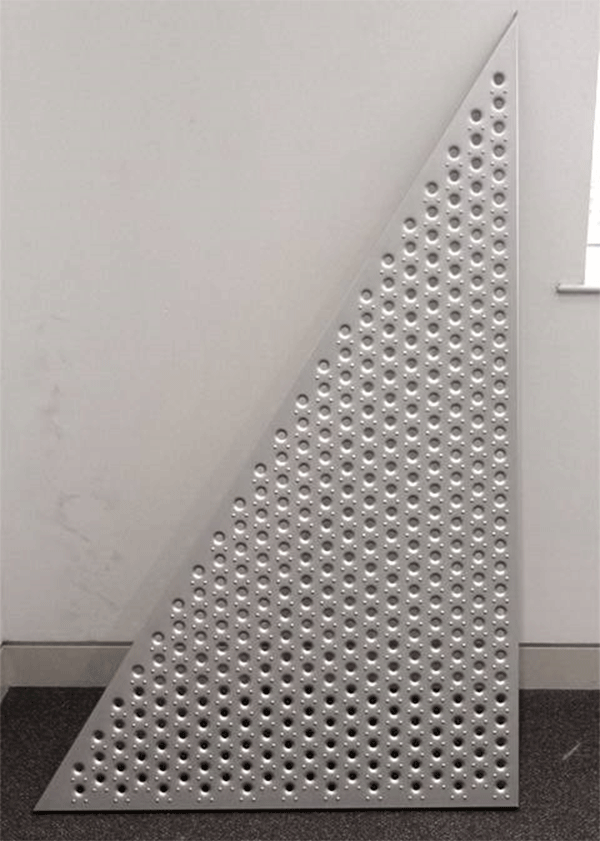

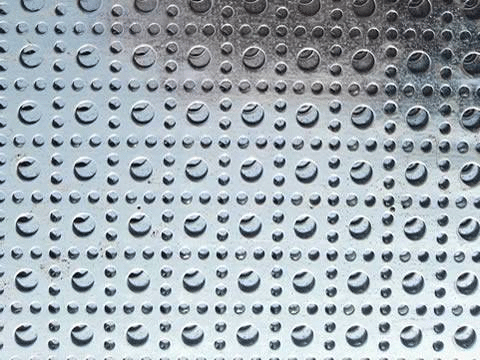

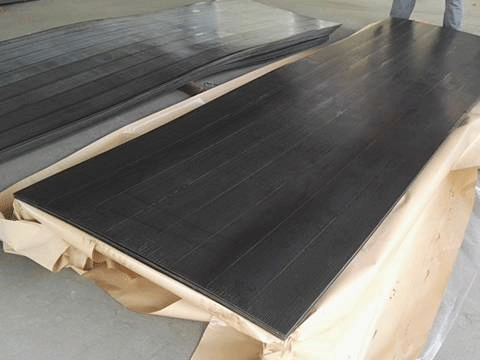

Embossed sheet (also known as anti-skid plate) is also a kind of perforated sheet with embossed patterns to increase frictions, disperse liquid and static effectively.

With the character of skid resistance, embossed sheets are widely used as stair treads, working platforms, panels of bridges, walkways, etc. We supply embossed sheets from mild steel, carbon steel, stainless steel, aluminum, copper, brass or any other materials suitable for perforation.

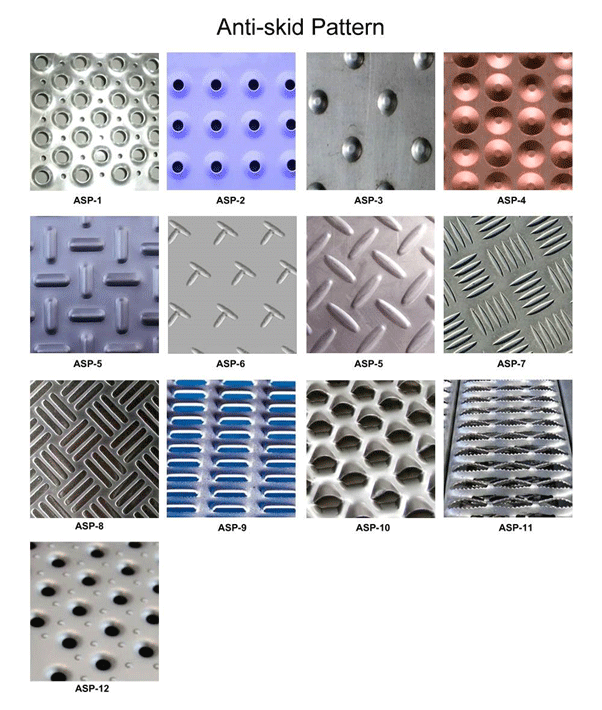

There are various embossed pattern for you to choose from as shown in the following picture, meanwhile, other patterns can be made to order.