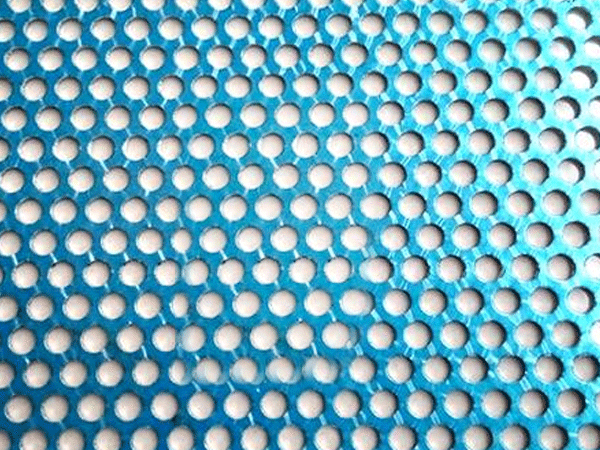

Perforation Material

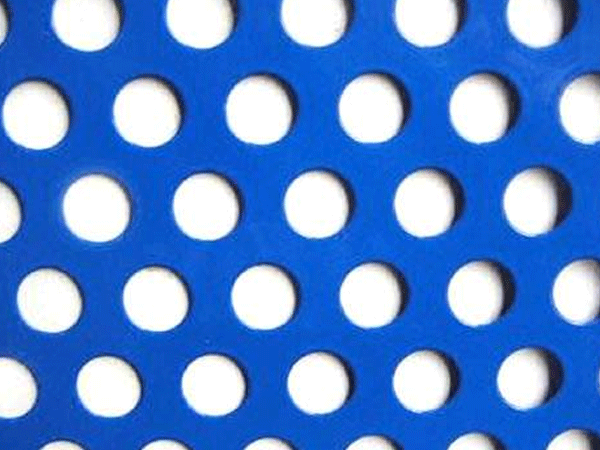

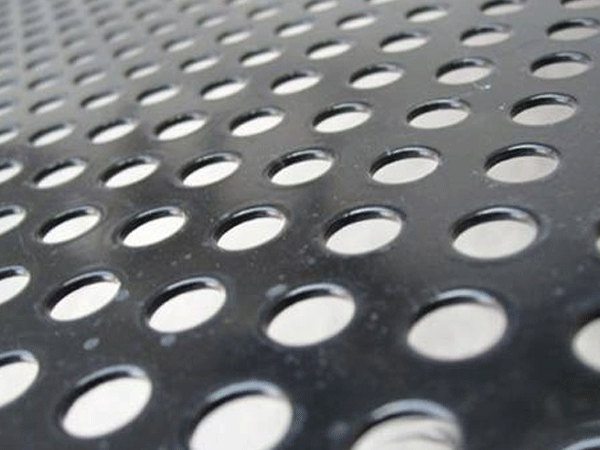

Why Can Perforated Steel Sheet Be Commonly Applied?

Perforated steel sheet is a kind of sheet products which is made through a serious of pouncing and stamping processes. It is often manufactured of mild steel (low carbon steel) or plain steel (also known as carbon steel) with a variety of perforation patterns, such as round, square, slot, hex, etc.

Generally speaking, the higher carbon content the perforated sheet has, the higher hardness with the lower ductility and weldability it will feature. To obtain desired effect, we supply multiple perforated steel sheets in different steel materials, such as AISI1018, 1144, 12L14 and 8620 steel, etc.

Compared to perforated stainless steel and aluminium sheet, this one is considered to be susceptible to rust and corrosion, but its low price, easy painting and plating make it a common choice. So it is often applied where high corrosion and rust resistance are not urgently needed. The perforated steel sheet can be galvanized or PVC coated for corrosion resistance as your requirements.

The perforated steel sheets we supply:

Hole shape: round, square & rectangular, slot, hexagon, oblong, diamond and other decorative shapes.

Sheet size: 1ft. × 4ft., 2ft. × 4ft., 4ft. × 4ft., 4ft. × 8ft., or tailored to your desired size.

Thickness: gauge 0.2 mm to 6 mm or as per your requirement.

Material: AISI1018, 1144, 12L14, 8620, ASTM A36, A653, A366, A513, etc. Other standards materials are also available as per your requirements.

| Comparison of main materials | |||

| Material | Tensile strength | Yield strength | Elongation at break (10%) |

| 1018 | 440 Mpa | 370 Mpa | 15 |

| 1144 | 74 5Mpa | 620 Mpa | 10 |

| 12L14 | 540 Mpa | 415 Mpa | 10 |

| 8620 | 530 Mpa | 385 Mpa | 25 |

| A36 | 400-500 Mpa | 250 Mpa | 20 |

| A653 | 400-550 Mpa | 250 Mpa | 20 |

| A366 | 300-350 Mpa | 180-240 Mpa | 42-48 |

| A513 | 600 Mpa | 500 Mpa | 10 |

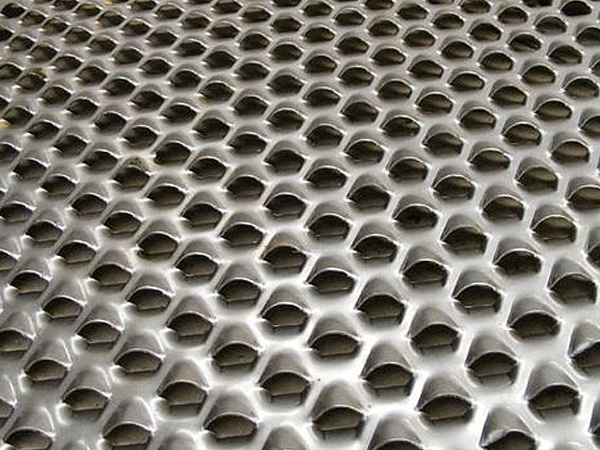

Perforated Stainless Steel Sheet – Best Solutions to Moisture Applications

Perforated stainless steel sheet is mainly made of 304 or 316 stainless steel sheet which is punched with a variety of hole patterns, including round, square, slot, diamond or your nominated hole shapes. The perforated stainless steel sheets we manufactured come with high quality and can be used in various circumstances

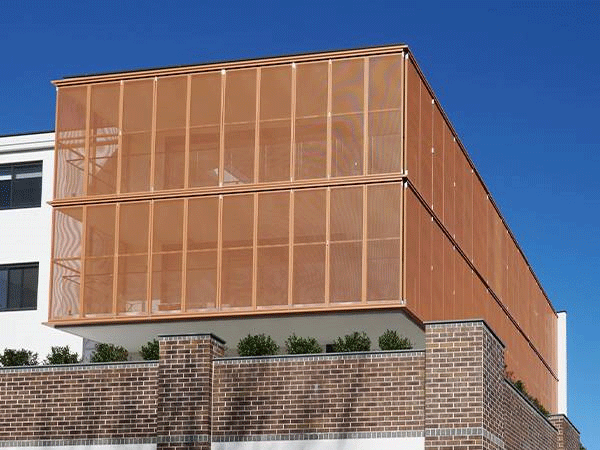

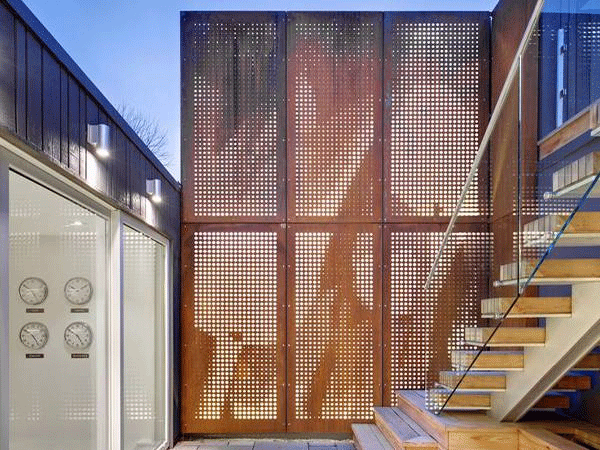

For the average person, stainless steel may seem just like traditional carbon steel, but the actual state of the affair is the material is more complicated which makes it anti-corrosive for usages in moist and humid environments. So there is no need of painting and coating for rust and corrosion resistance any more. Perforated stainless steel sheet is suitable used for sunshade panels for high building and leisure place.

Three material types of perforated stainless steel sheets:

According to the crystalline structure of perforated stainless steel, it can be classified into three types: Austenitic, Ferritic and Martensitic.

Austenitic steel, containing high content of chromium and nickel, is the most corrosion resistant steel providing incomparable mechanical properties, thereby, it becomes the most common type of alloy, accounting for up to 70% of all stainless steel production. It is non-magnetic, non-heat-treatable but it can be successfully welded, formed, meanwhile being hardened by cold-working.

- Type 304, composed of iron, 18 – 20% chromium and 8 – 10% nickel; is the most common grade of austenitic. It is weldable, machinable for various applications, except in salt water environments.

- Type 316 is made of iron, 16 – 18% chromium and 11 – 14% nickel. Compared to type 304, it has better corrosion resistance and yield strength with similar weldability and machinability.

Ferritic steel is straight chromium steel without nickel. When it comes to corrosion resistance, the ferritic is better than martensitic grades but inferior to austenitic stainless steel. It is magnetic and oxidation resistant, additionally; it has perfect working performance in marine environments. But it cannot be hardened or strength by heat treatment.

- Type 430 features high resistance to corrosion from nitric acid, sulfur gases, organic and food acid, etc.

Martensitic steel, same as Ferritic steel, is chromium steel with no nickel. It is magnetic and heat-treatable. It features the highest hardness among all stainless steel products for applications where hardness, strength and wear resistance are required due to higher levels of carbon.

- Type 410 contains lowest alloy content when comparing to other martensitic steel.

Specifications:

- Hole shape:round, square & rectangular, slot, hexagon, oblong, diamond and other decorative shapes.

- Sheet size: × 4ft., 2ft. × 4ft., 4ft. × 4ft., 4ft. × 8ft., or tailored to your desired size.

- Thickness: gauge 1.6 to 6 mm or as your requirement.

- Material:304, 316, 430, 410, 301, 302, 303, 321, 347, 416, 420, 430, 440, etc. Other standards materials are also available as your requirements.

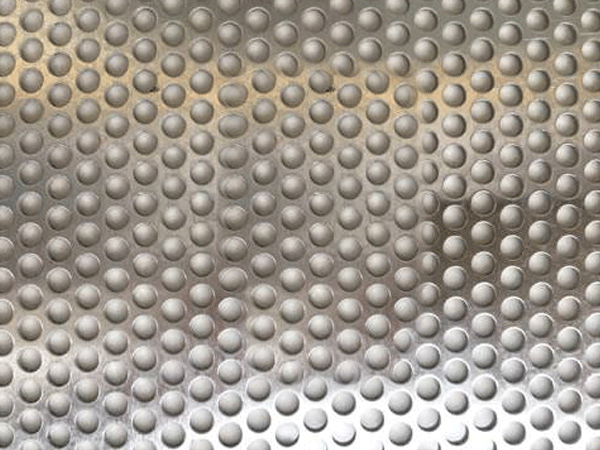

Why Perforated Aluminum Sheet Essential in Food Processing?

Perforated aluminium sheet is excellent at corrosion resistance due to its oxide skin formed after contacting with moist air.

Compared to other perforated steel sheet, perforated copper sheet with similar gauge, this one is relativity light weight. Meanwhile high ductility and reflection to heat and light make it widely used as wall or ceiling panels, sunshades of platform, etc. Its perfect filtration property and non -toxic character allows it being used as drying sieve, production filtration, especially in food processing.

It is worthwhile to note that the aluminium is rust free, therefore, there is no need of any anti-rust painting and maintenance all through its service life. For decorative applications, it can be anodized to improve color and strength or through some surface treatments to reach your desired effect, such as brilliant and high polished, reflective shine or a dull mill finish, etc.

What kind of perforated aluminium sheet can we supply?

Hole shape: round, square & rectangular, slot, hexagon, oblong, diamond and other decorative shapes.

Sheet size: 1ft. × 4ft., 2ft. × 4ft., 4ft. × 4ft., 4ft. × 8ft., or tailored to your desired size.

Thickness: gauge 1.6 to 6 mm or as your requirement.

Material: 2211, 2024, 3003, 5052, 6061, 6063, 6262, 7075. Other standards materials are also available as your requirements.

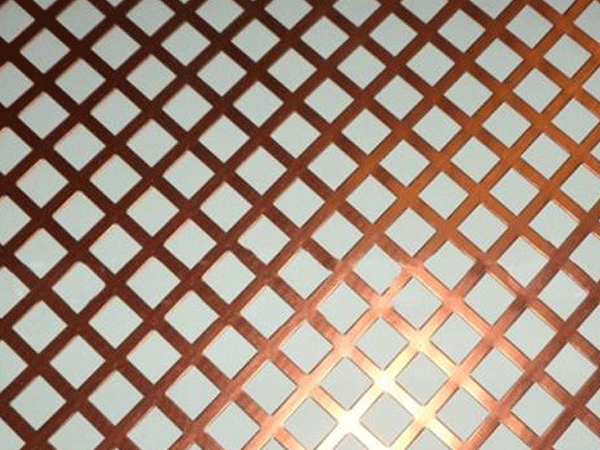

Perforated Brass Sheet – Corrosion Resistant, Durable & Aesthetic

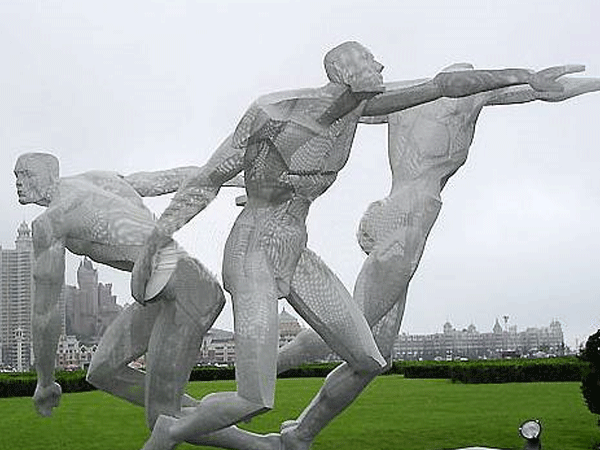

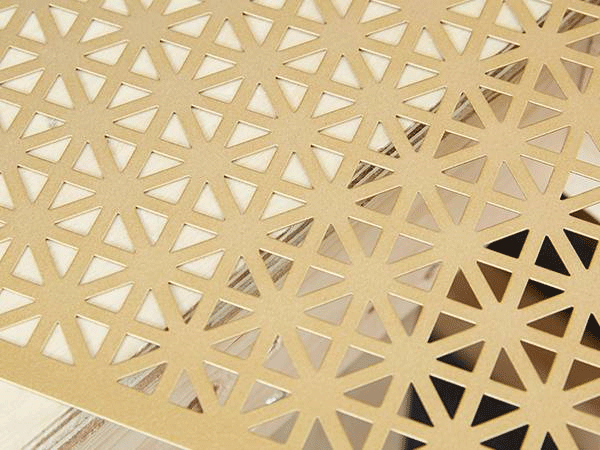

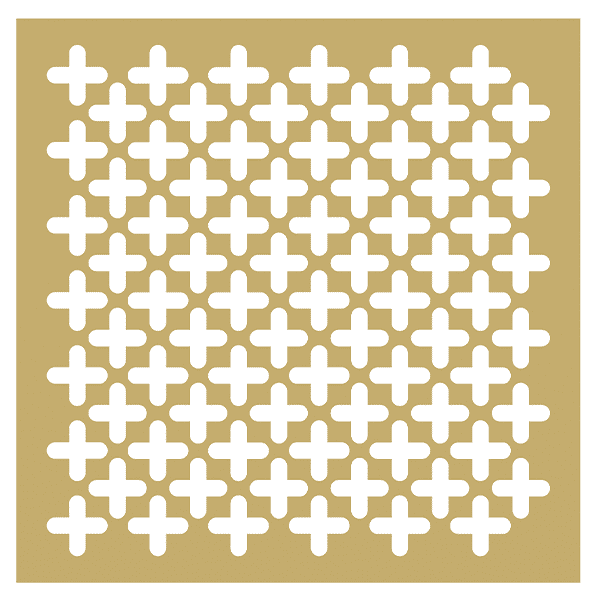

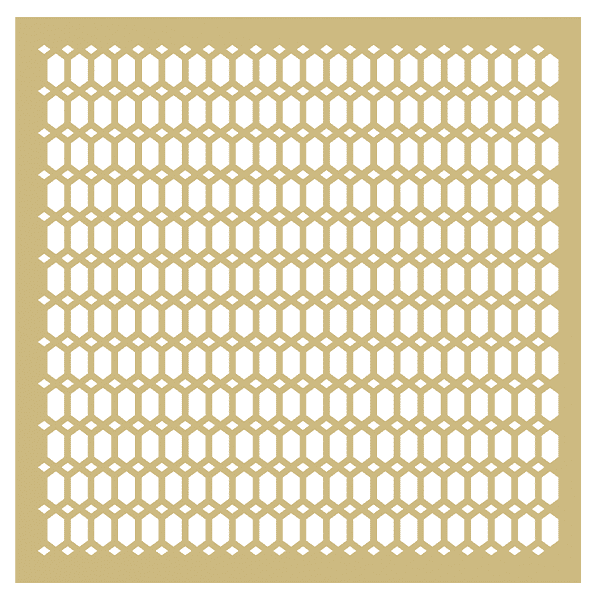

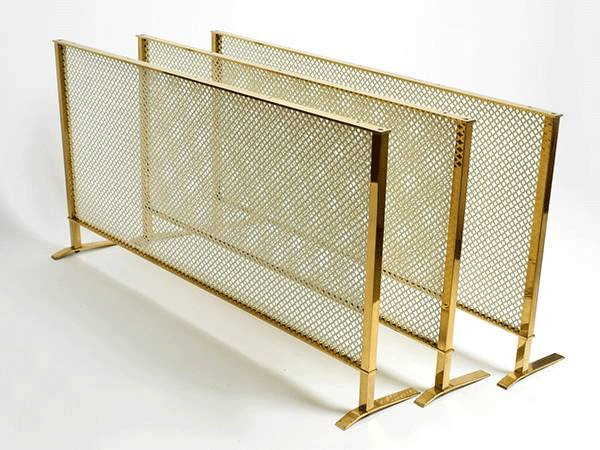

Perforated brass sheet, also called brass perforated plate, is widely used in architectural design, not only because of its appearance and various hole patterns, but also has good mechanical properties, and good plasticity, good cutting, easy to weld, and corrosion resistance. Ideal for use in cabinet and door panel inserts, radiator covers, ventilation and general interior design screens.

Specification:

- Sheet Sizes:2000 mm × 1000 mm, 1000 mm × 660 mm and other customized sizes

- Surface Finish:mill, brushed brass, antique, satin brass, bright polished brass

- Hole Patterns:round, square, diamond, hexagon, flower, and other decorative customized patterns

Applications:

- Architectural Decoration:building exterior walls, ceilings, partitions, balcony railings, staircase handrails, etc.

- Furniture Decoration:cabinets, screens, tables, chairs, etc.

- Automotive Decoration:radiator hoods, air intake grilles, body trim, etc.

- Electronic Products Components:casing, heat sinks, etc.

- Filtration Industry:industrial filters, screens, isolators, etc.

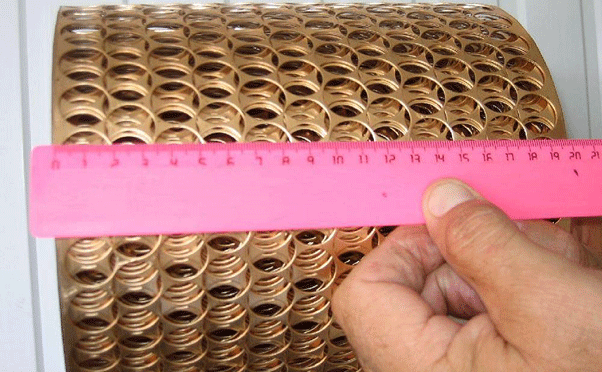

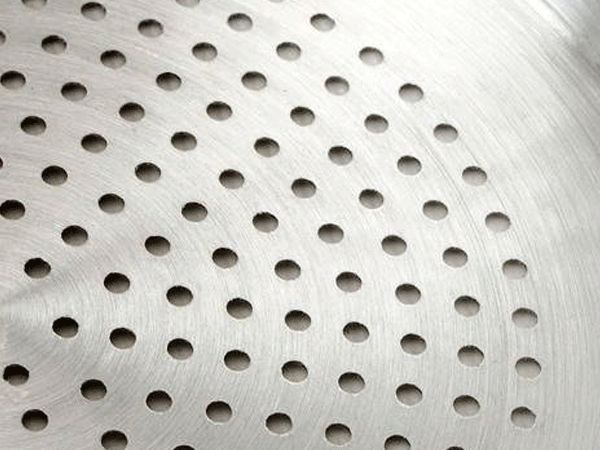

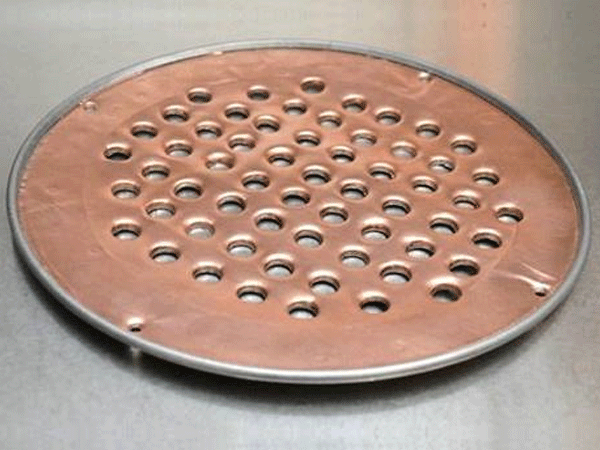

Perforated Copper Sheet

Good Choice for Decoration – Perforated Copper Sheet

Copper, as one of the first to be utilized metals, has been playing an important role in human life. Generally speaking, the purification of copper needs great amount of electricity and the pure copper is soft, so copper alloys are more commonly used. To adjust the strength, hardness and corrosion resistance, some other metal elements are added. For example, brass, the most-used alloy, applies to zinc as main added elements. When the main added ingredient is tin, the alloy is named bronze.

We mainly supply perforated copper sheet and perforated brass sheet, which are free of rust with corrosion resistant surface of copper carbonate formed of being exposed to the weather. The warm color and noble appearance make it popular as decoration grilles whether interior design or exterior trim. Meanwhile, it can be used to secure ceiling, protect machine equipment, insulate sound, sieve grain and forage, etc.

Perforated cooper or brass sheets are often unfinished due to its high corrosion resistance, but to suit specific application, it also can be coated with a variety of finished. Furthermore, the sheets are often polished to provide a superior appearance, such as brilliant polished, reflective shine or dull mill finish.

Choosing copper or brass sheet is, indubitably, a sign of environmental protection on account of its recycled character with a virtually unlimited lifespan. What are you waiting for? Come and take the high sustainable perforated copper sheet!

Specification:

- Hole shape:round, square & rectangular, slot, hexagon, oblong, diamond and other decorative shapes.

- Sheet size: × 4ft., 2ft. × 4ft., 4ft. × 4ft., 4ft. × 8ft., or tailored to your desired size.

- Thickness:gauge 1.6 to 6 mm or as your requirement.

- Material: 110, 220, 230, 260, 268, 270, 335, 340, 342, 353, 443, 444, 445, 464, 465, 466, 467, 614, 705, 715. Other standards materials are also available as your requirements.