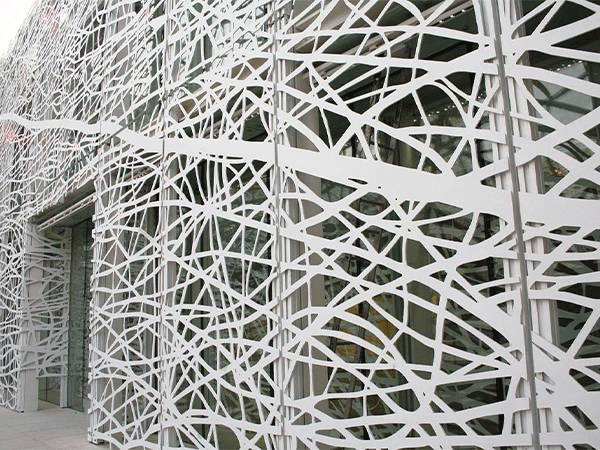

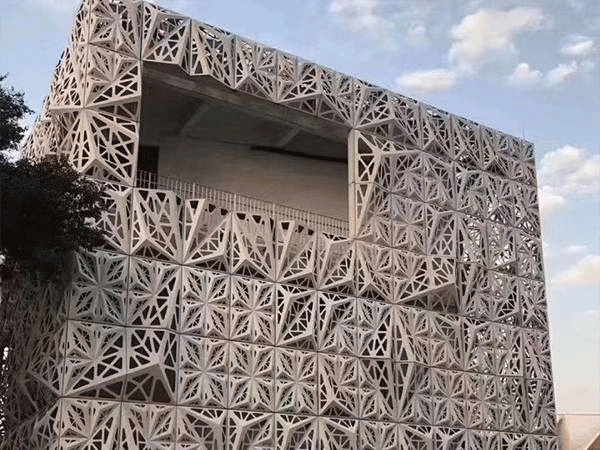

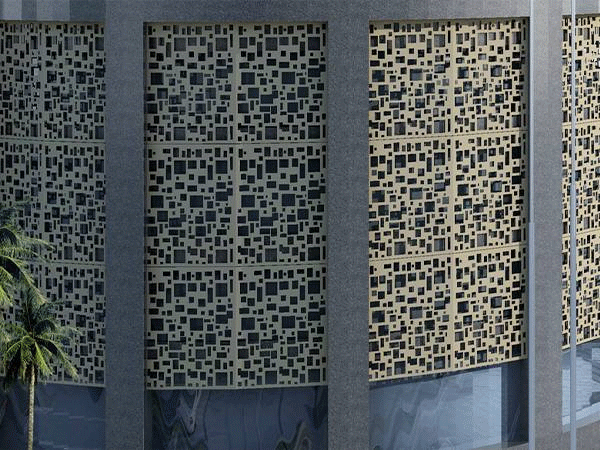

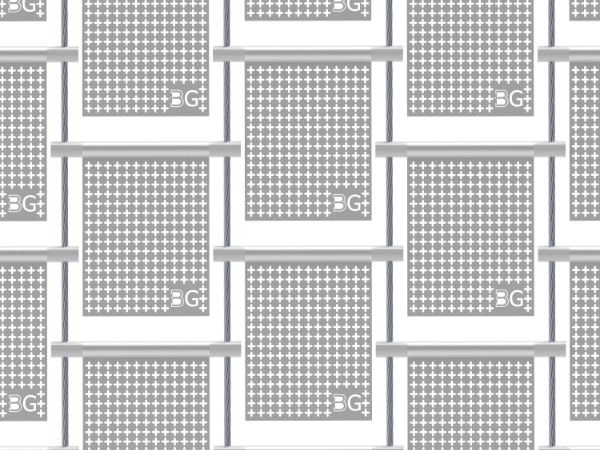

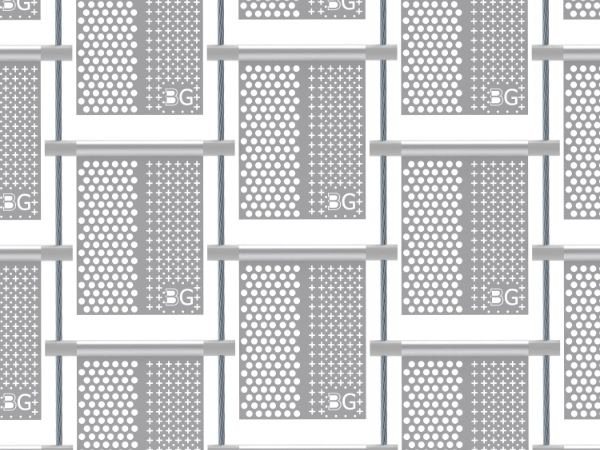

Aluminium Carved Facade Panels with Custom Patterns & Better Performance

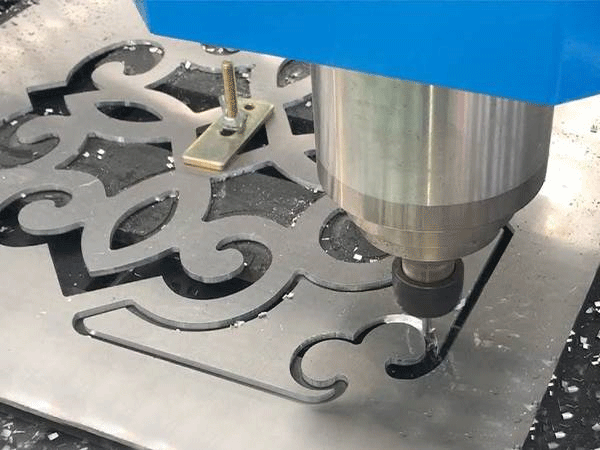

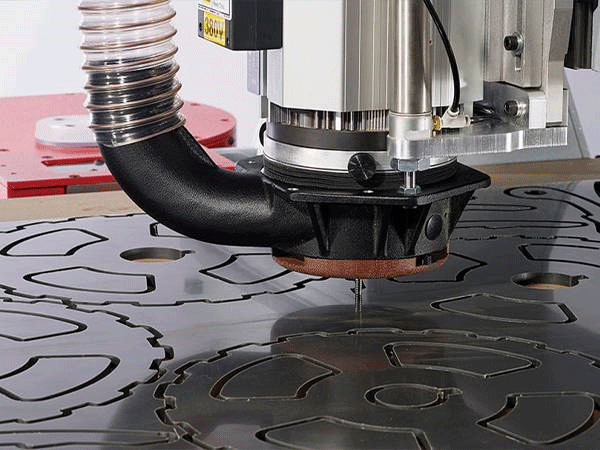

Aluminium carved facade panels are a popular building facade option for architects and designers due to its versatile and lightweight features. Featuring high precision and high efficiency, CNC cutting technology is employed to form irregular, complex patterns that perforated metal cannot achieved and satisfy virtually any architectural design or demand. In addition, our aluminium facade cladding panels are fabricated of thicker panels to offer better wind resistance and weather resistance. Besides, powder coated finish and PVDF coated finish are available to offer not only better corrosion resistance but also a more attractive appearance to make all your brilliant ideas or designs come true.

Specifications

- Material:aluminium Alloy AA1100, 1200, 3003, 3014, 5005, 5015, 6063 etc.

- Thickness: 1.0–16 mm

- Standard size:1 m × 2 m, 1.22 m × 2.44 m, 1.4 m × 3.0 m (Max. Width is 1.5 m and Max. Length is 6.0 m). Special sizes can be customized.

- Patterns:both 2D and 3D patterns are available and customized according to CAD drawings.

- Colors:golden, bronze, antique brass, rose golden and other RAL colors.

- Surface finish:anodized, powder coated or PVDF coated.

- Surface treatment:Powder coating, PVDF coating

- Patterns:Customized according to drawings or designs.

Benefits

- Practically unlimited choice of patterns, colors, shapes and sizes;

- High precision, high efficiency, smooth and beautiful surface;

- Lightweight, great corrosion resistance and wind resistance;

- Aluminium offers great ductility and can perfect fit all building exterior wall modelling;

- Flat, curved, bend, triangle, arch and other shapes are available;

- Both powder coating and PVDF coating offers excellent resistance to exterior weathering such as fading, color change, chalking and cracking.

- With a maximum thickness of 16 mm, strong and durable, not easy to break.

- It allows the passage of air and natural light to provide a visually striking facade bespoke to the building;

- It can be 100% recycled and will not do any harm to the environment.

Application

Our aluminium facade cladding panels are widely used in both interior and exterior decorations and act as wall cladding, facade, fence and privacy screens in offices, hospitals, museums, shopping malls, stadiums etc.

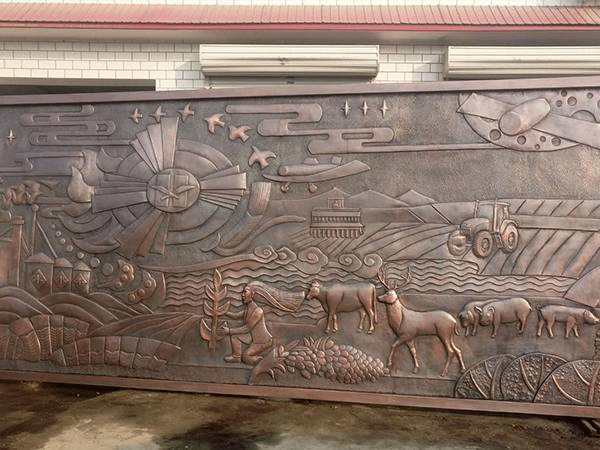

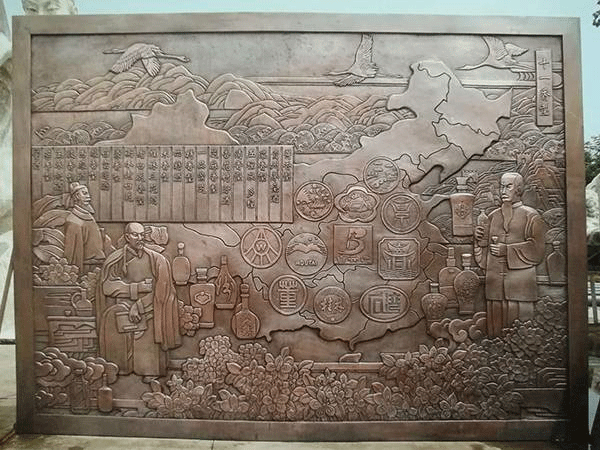

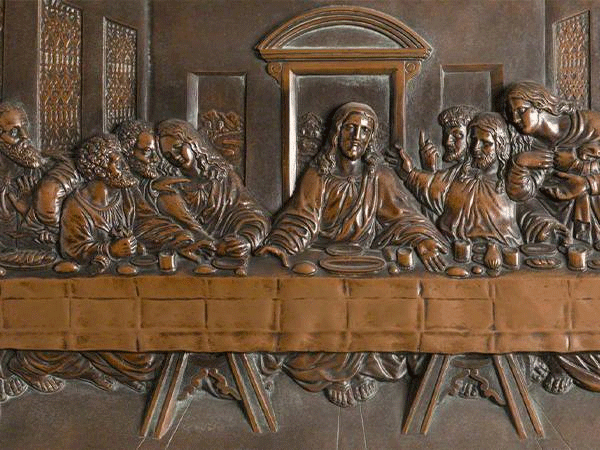

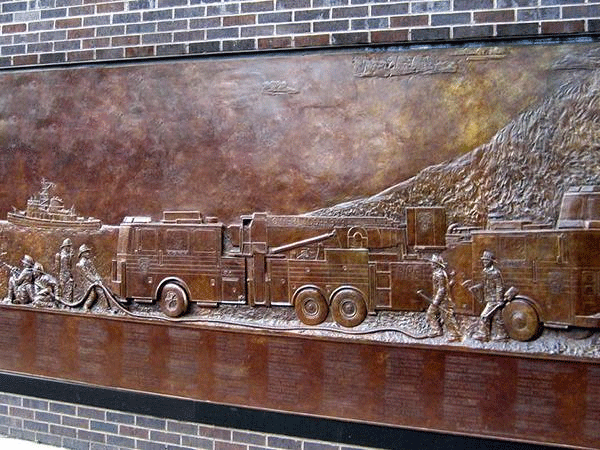

Bronze Relief Sculpture for Amusement Parks, Theme Parks & Play Grounds

Bronze relief sculpture is a kind of sculpture created in relief to give the impression that the sculpted material has been raised above the background plane. It is a combination of two-dimensional pictorial arts and the three-dimensional sculptural arts to tell stories vividly. We can create a wide range of bronze relief sculptures according to your pictures or drawings to depict all stories you want to express. It is widely used in amusement parks, theme parks, gardens, restaurants, play grounds and other public areas to enrich the cultural atmosphere and add a unique charm to the space where it is placed.

Specifications

- Material: Bronze sheets and plates

- Thickness: 1.0–16 mm

- Standard size: 1 m × 2 m, 1.22 m × 2.44 m, 1.4 m × 3.0 m (Max. Width is 1.5 m and Max. Length is 6.0 m). Special sizes can be customized.

- Surface finish: High polished or honed, ancient time finish;

- Color: Any bronze colors

- Patterns: Customized according to, pictures or drawings.

Benefits

- Custom patterns, colors and sizes are available to meet your specific decoration demands.

- Bronze offers great ductility, corrosion resistance and weather resistance.

- Bronze relief sculptures are usually anchored to a flat surface, like a wall, to offer better stability.

- Several panels or sections may work together to represent a sequence of scenes.

- It can be 100% recycled and will not do any harm to the environment.

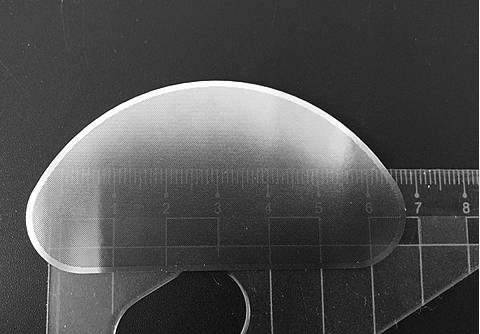

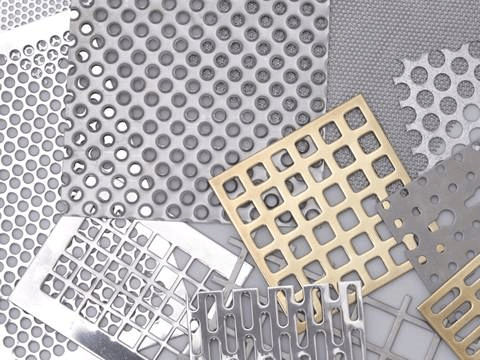

Etched Plates in Stainless Steel & Plain Steel

Regarding the punched metal plates, the minimum hole PEMPL can supply is 0.8 mm. But it can not meet the filtration need, especially the application requiring extremely fine holes. Thus, PEMPL adopts another advanced production line – metal etching, which creates chemically micronic flow channels on the surface of metal panel, to enable precision rate ranging from 30 μm to 100 μm absolutely.

This etched plates can be used as fiber filter, textile filter and other filters in food and beverage industrial such as a coffee filter to ensure its mellow smooth taste. The small hole also makes the plate prevent unwanted things out, such as insects, even dust.

Advantages:

- Super fine holes for high precision filtration.

- No welding, no burs, no broken points and no plugging holes ensure the most reliable filtration.

- Available in thousands of different plate shapes and hole patterns.

- No need open tooling or moulding for low cost.

- High tolerance ± 0.01 mm.

Specification:

- Material: stainless steel and plain steel.

- Plate thickness: 0.1 mm – 1 mm.

- plate size: 500 mm × 600 mm.

- Hole size: Min. 0.03 mm.

Hole shape: round hole, slot hole and other custom patterns.

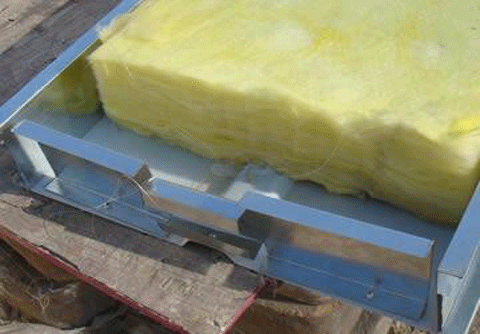

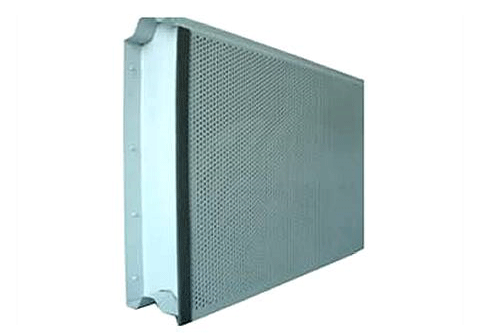

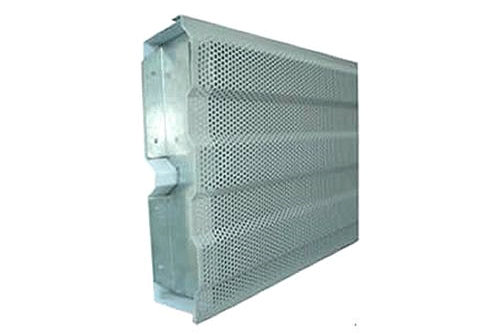

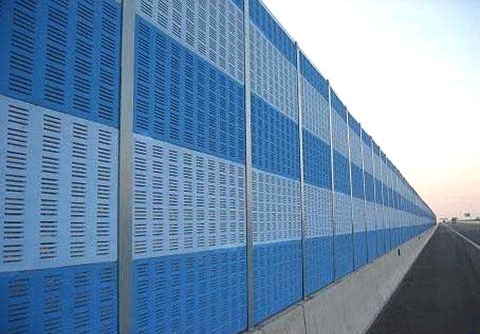

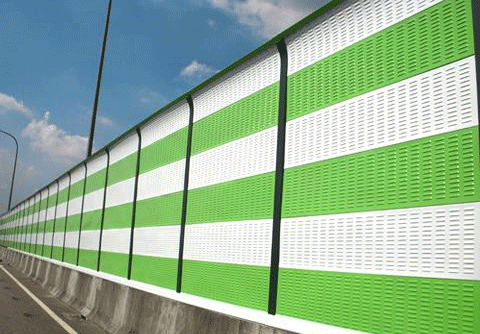

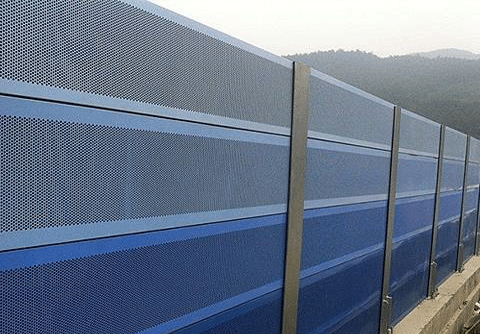

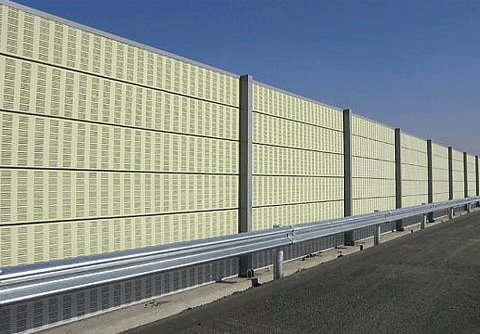

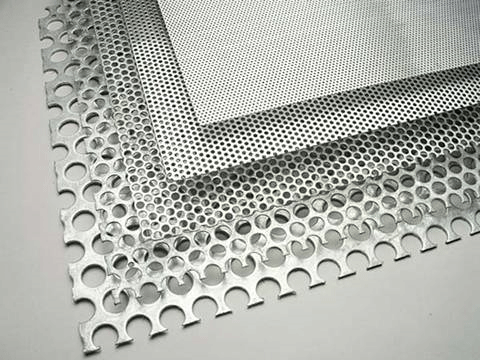

Perforated Metal Noise Barrier

Galvanized or Aluminium Noise Barrier for Highway and Railway

Noise barrier, also called sound barrier, is a type of fence barrier used in the highway, railway, residences and other places for sound insulation and reduction. Perforated metal noise barrier with light weight, firm structure durable and other features are popular in both industrial and commercial applications. Here are the detailed information of noise barrier, refer to them and choose the perfect one you like.

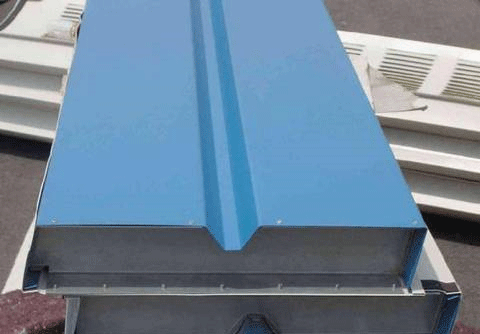

Structure of noise barrier

Noise barrier is a three-layer structure.

- The first layer is the perforated metal sheet. The common material of perforated metal sheet is aluminium. Mild steel, galvanized steel or powder coated steel sheet are also available. The hole type of perforated metal sheet can be micro holes or louver holes.

- The second layer is sound absorbing material infill. The sound absorbing material has excellent sound or noise absorbing performance, it can reduce the noise and keep quite. The main infill material is glass wool. Other absorbing materials are available.

- The third layer is metal sheet. The material of metal sheet is same as the perforated metal sheet. But there is no any hole on the metal sheet

Types of noise barrier

- According to the hole pattern:

- Round hole.

- Louver hole.

-

According to the panel surface:

- Flat panel.

- Uneven panel.

-

-

According to the barrier shape:

- Common type.

- Arc-shaped barrier.

- Knuckling barrier.

- Top arc-shaped barrier.

- Top knuckling barrier.

- Irregular shape barrier.

-

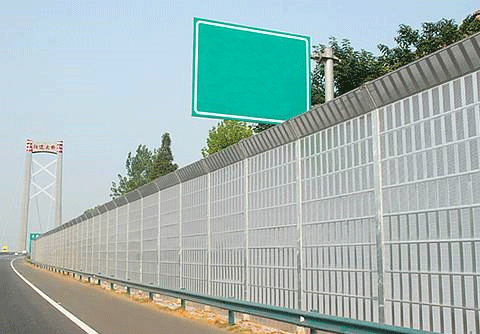

Installation of noise barrier

The noise barrier is easy to install. The main installation accessories are H post and bolts and nuts.

When you install the noise barrier, you should fix the H post on the concrete ground and then fix the noise barrier panels in the space between the posts. And then fix the top of H post. Refer to the technology support about detailed installation of noise barrier.

Specifications of noise barrier

- Material: Stainless steel sheet, mild carbon steel sheet, aluminium steel sheet.

- Metal plate Thickness: 0.6mm, 0.7mm, 0.8mm, 1.0mm.

- Barrier forming thickness: 80mm, 100mm, etc.

- Length: 1960mm, 2460mm.

- Width: Commonly is 500mm.

Features of noise barrier

- Three layer structure for better noise absorbing and weakening.

- Easy to install. It does not need special tools.

- The aluminum noise barrier is lighter than other materials.

- Different surface treatment can ensure the long service life of noise barrier.

- Various colors for choice. Different colors to be painted onto the noise barrier to suit the surrounding environments.

- It can be used with different other types of noise barrier to suit different application.

Application of noise barrier

Noise barrier has a wide range of application it can be used in the noise places to absorb and reduce noise. In this way, we can supply a quiet and silence life for people. It can be used in the places in the bellowing.

• Highway.

• Railway.

• Subway.

• Factory.

• Construction site.

• Residences.

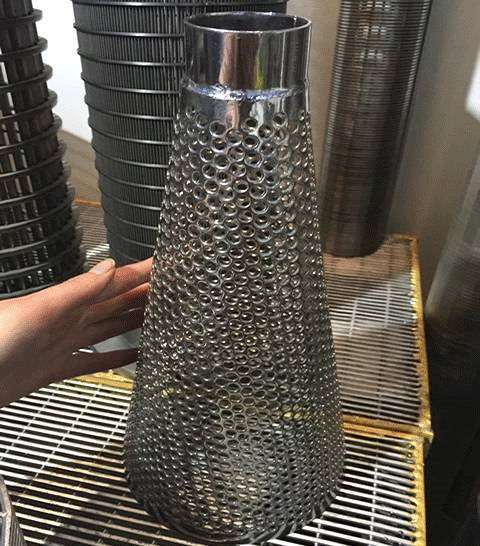

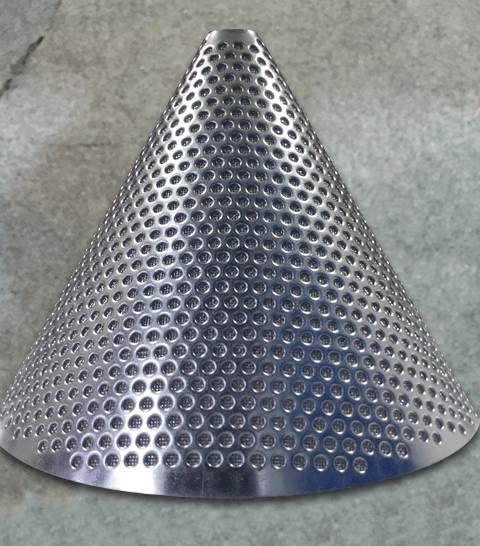

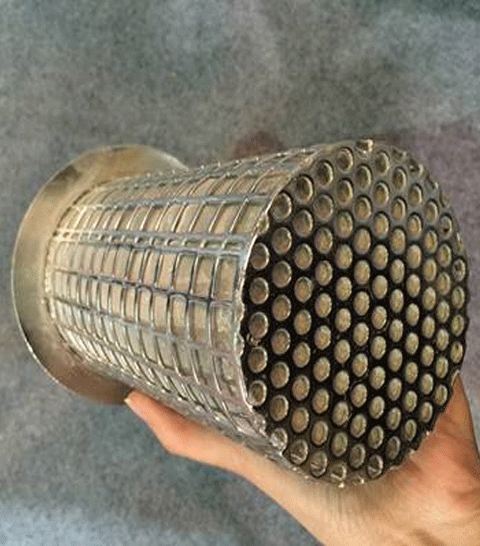

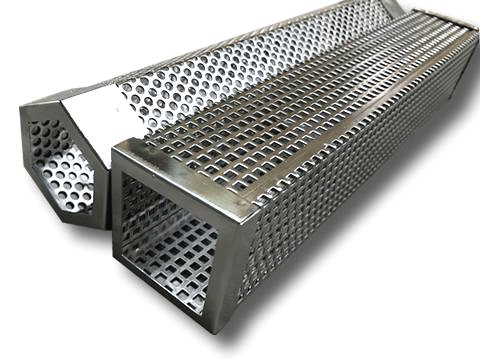

Perforated Filter - Smooth Surface & Firm Structure

Perforated filter made of perforated sheet, can be classified into perforated cylinder filter, perforated basket filter, perforated cone filter and perforated tube filter. Generally it is made of stainless steel, carbon steel, aluminium or copper sheet and the hole shape is round or square. With accurate filtration rate, perforated filter can filter a large variety of fluids and retain almost any size solids. With high mechanical strength, perforated filter is mainly used in petroleum, chemical industry, pharmacy, food making filtration and sewage water filtration, etc.

Specifications

- Material: stainless steel, carbon steel, aluminium, copper, galvanized steel sheet, etc.

- Sheet thickness: 3 gauge – 36 gauge.

- Layers: single layer or multiple layers.

- Edge processing: with wrapping edge or metal flange.

- Perforated hole patterns: round, square, slot, etc.

- Filter precision: 2-2000 µm.

Features

- High porosity and excellent permeability.

- Corrosion resistance and high temperature resistance.

- Accurate filtration precision.

- Easy processing and installing.

- Easy forming, painting, polishing, welding and cleaning.

- Firm structure and different hole patterns.

Applications

Perforated metal filter is widely used in petroleum, chemistry, metallurgy, machine, medicine, automobile industries for distillation, absorption, evaporation and filtration processes, so as to eliminate the impurity and foam mixed in the gas and liquid.

- Filtration of air: air filters, vacuum filters, filtration of corrosive gases, cage ventilation, etc.

- Filtration of liquid: ceramics polluted water cleaning, beverage, disposal of sewage water, filtration of corrosive liquids, beer brewing filter, etc.

- Filtration of solid: glass, coal, food processing industry, cosmetics, fluidised beds, etc.

- Filtration of oil: oil refining, hydraulic oil, oilfield pipelines, etc.

- Filtration of other fields: textile industry, insulation industry, automotive industry, chemical industry, metallurgy, pharmacy, electronic field, etc.

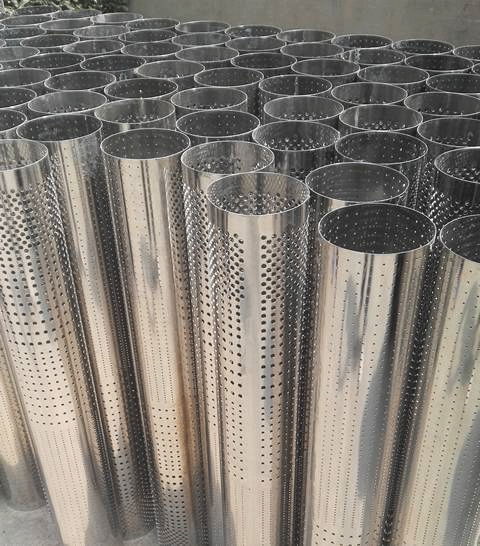

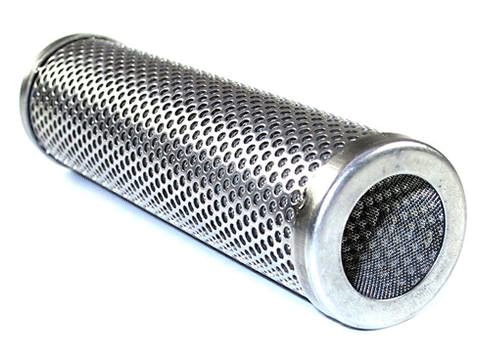

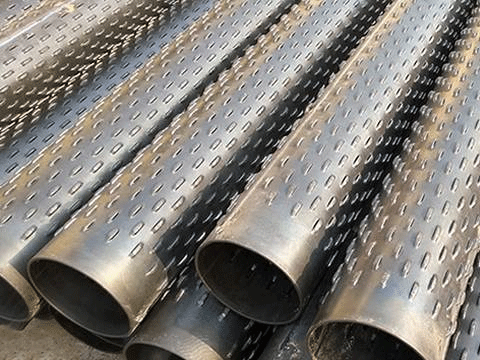

Perforated Tubes – Purify Liquids and Sieve Materials

Perforated tubes are made of aluminium, stainless steel, carbon steel and alloy sheet. According to opening diameter, we design the width of plate and punch holes customized by you. Then these plates are rounded in a spiral or straight strip and welded by argon arc welding. The perforated filter tube surface is processed by electrolytic polishing, galvanization, sandblasting, pickling and passivation.

With durable materials and various models, perforated tubes can filter liquids, solids and air or sieve different materials to ensure the purity. Weakening noise and granary ventilation are also their important functions. With good acid and alkali resistance, sieving tube is a very practical product for filtering ceramic powders, glass materials, plastic materials, soils, mineral aggregates, drug particles, metal powders, etc.

Application of perforated tube:

- Filter liquids and air, such as water, oil, etc.

- Sieve different materials and remove impurities, such as in food, pharmaceutical, chemical and environmental protection industry.

- As various frameworks of filter elements.

- Weaken the noise.

- Used for granary ventilation.

Perforated tube features:

- Uniform welds and good pressure resistance.

- Accurate roundness and straightness.

- Smooth and flat surface.

- High filter precision.

- Also can cut the noise and ventilate.

- Resist acid, alkali, low and high temperature, so has a long service life.

Perforated tube specifications:

- Materials:aluminum plate, stainless steel plate, galvanized steel plate, alloy plate, iron plate, carbon steel plate, copper plate.

- Thickness:4–15 mm.

- Tube length:10–6000 mm, or tailored to your desired size.

- Tube outside diameter:6–200 mm.

- Wall hole pattern:round, rectangular, square, hexagonal, oval, plum blossom, etc.

- Hole diameter:3–10 mm.

- Open area:23%–69%.

- Filter precision:2–2000 μm.

- Welding process:

- spot welding or full welding.

- straight welding or spiral welding.

- argon arc welding.

- Surface:electrolytic polishing, galvanization, sandblasting, pickling and passivation.

- Frame structure:margin or no margin.

- Packing:moisture-proof paper, pallet, wooden container.

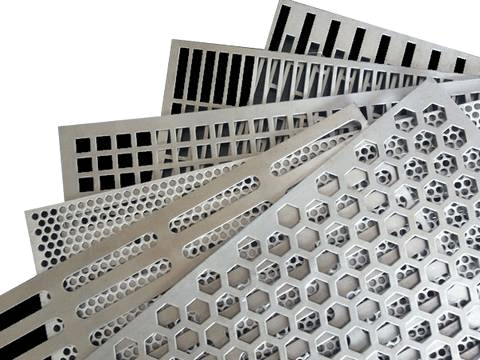

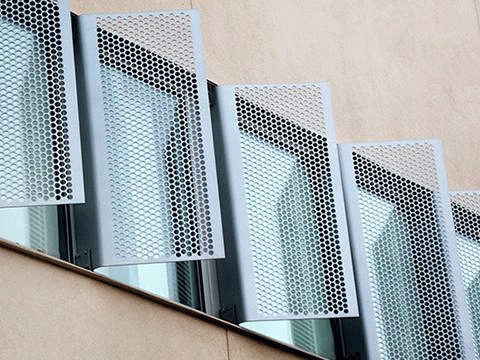

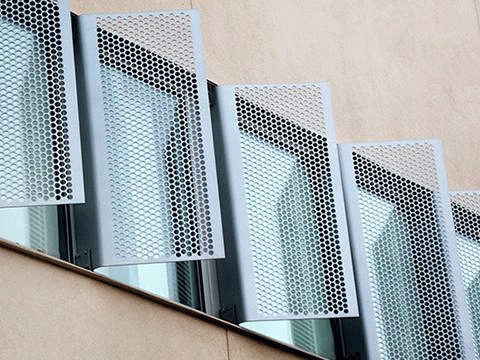

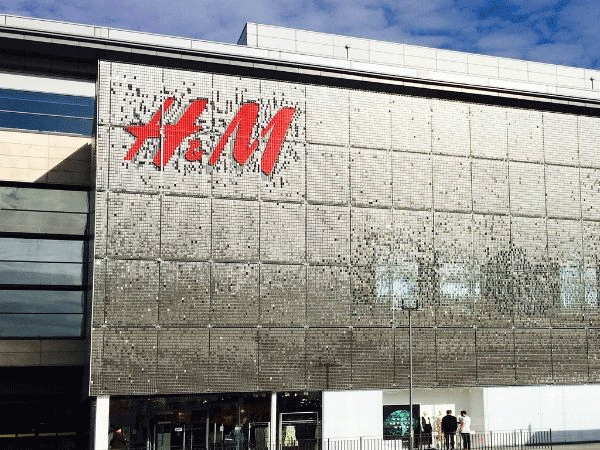

Perforated Sunshade Panels

Perforated Sunshade Panels Shade and Decorate Large Buildings

Perforated Sunshade Panels are made of high quality aluminum plate, aluminum alloy plate, stainless steel plate, etc. Adopting advanced computer numerical control technology, we manufacture perforated sunshade panels by punching press and stamp by different molds. The metal perforated sun visor surface is coated with powder, fluorocarbon, PVC, or galvanized. According to your shade and ventilation needs, we can design the open area and arrangement of holes reasonably.

With durable materials and scientific structure, our perforated plate panels can cut out direct sunlight, reduce solar heat gain and improve the interior air condition. They also can be used as decoration with beautiful appearance. Therefore, perforated sheet is a kind of energy saving, environmentally friendly and modern shade decoration products which soothes your sense of oppression caused by closed place, opening your field of vision.

Perforated sunshade panels specifications:

- Material:aluminium plate, aluminium alloy plate, stainless steel plate.

- Thickness:2–2 mm.

- Hole pattern:round, square, oval, diamond, hexagonal, rectangular, flower shape. Other hole shapes and patterns can be customized.

- Hole size (diameter or width):2–125 mm, or tailored to your desired size.

- Open area:10% – 50% or as your requirements.

- Panel width:100–1000 mm.

- Panel length:1800, 2400, 3000 and 3600 mm, or tailored to your desired size.

- Surface:galvanized, PE/PVC coating, powder coating, fluorocarbon coating, anodic oxidation.

- Frame structure:margin or no margin.

- Packing:

- perforated sunshade panels in rolls.

- perforated sunshade panel sheets on pallets or in wooden container.

Application of perforated sunshade panels:

- Be applied to the top or sides of large buildings, such as shopping malls, high-class hotels, conference rooms, stations, exhibition halls, museums, office buildings, dormitories, teaching buildings, laboratories, factories and so on.

- Be used to set up parking lot, leisure space, etc.

Perforated sunshade panels features:

- Can cut out direct sunlight, reduce unwanted solar heat gain and improve the interior air condition, and are fireproof.

- Play an important role in anti-theft.

- Well lighted, ventilated and mitigate the green house effect.

- Good reflectivity and do not cause light pollution.

- Non-corrosive, recyclable and has a long service life.

- Smooth surface and easy clean.

- As a beautiful modern decoration.

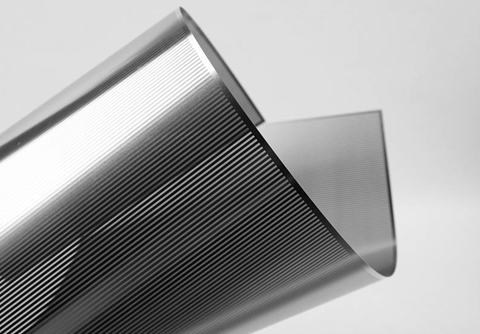

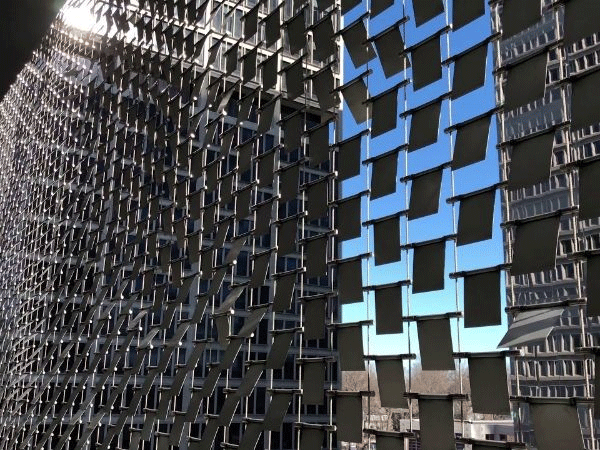

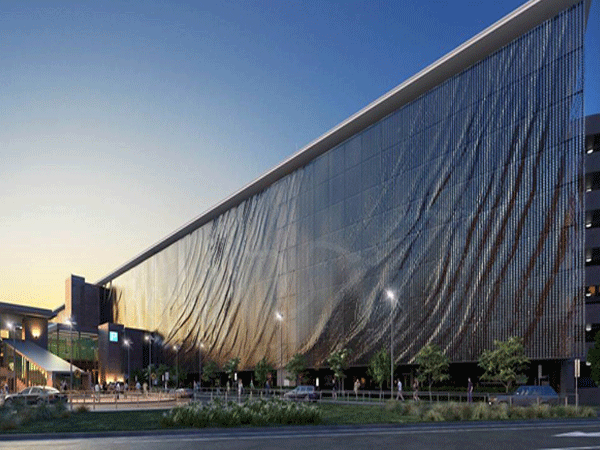

Perforated Kinetic Facade

Perforated kinetic facade is a kind of perforated metal plate used as decorating facade, whose decorative effect is different from decorative effect of common metal facade. It is kinetic and when the wind blows, perforated kinetic facade rises and falls as waves. Perforated kinetic facade is made of sheet metal processed by punching equipment, and is widely used for the decoration of various large buildings. The shape of its holes can be produced as your requests. Perforated kinetic facade is usually made of aluminium (or aluminium alloy), stainless steel, copper, carbon steel and so on. Surface by spraying, anodizing and other special treatment to make it strong, corrosion-resistance and durability. The buildings decorated with it can not only make you have a visual enjoyment, but also provide you with a comfortable environment.

Specification of perforated plate for kinetic facade:

- Material: aluminium / stainless steel

- Surface: mirror/brushed

- Surface treatment

- Titanium Coated for stainless steel

- Anodizing, Powder Coating or PVDF Coating for Aluminum

- Sheet thickness: 0.6–0.8 mm

- Standard sheet sizes: 150 × 180 mm, 150 mm × 190 mm, 120 mm × 120 mm, 120 mm × 150 mm, 90 mm × 120 mm (other sizes can be customized)

- Sheet vertical spacing: 30–50 mm (varies based on different projects)

- Colors: customized.

- Stainless steel wire rope diameter: 3.0 mm, 5.0 mm, 6.0 mm or 8.0 mm.

- Rail diameter: 6.0 mm, 8.0 mm or 10.0 mm.

Perforated kinetic facade features:

- Various hole sizes, aesthetic appeal and a special visual effect.

- Light weight, high strength, shock resistant.

- Fire proof, corrosion-resistant, stay durable color, long time service life guaranteed.

- Regulate the incidence of light, shading and sun protection, natural ventilation, well weather-resistant.

- Good thermal insulation and sound insulation.

Application:

Perforated kinetic facade is applied to the facades of large buildings, such as, offices, dining halls, airport buildings, shopping malls, theaters, museum buildings, exhibition halls, concert halls, etc.

Anti-skid Stair Steps in Work Platform, Stairs to Ensure Safety

Anti-skid stair treads are made of aluminium plate, galvanized pate, stainless steel plate, carbon steel plate. Adopting numerical technology, we punch the metal plate into different hole patterns and make shear bending. Then we weld these plates, forming a anti-skid plate.

With high quality materials, safety grating stair treads are applied as anti-skid stair steps for bridge walkway, production workshop, operating platform, in industrial plants, sewage treatment plant, brewery, paper industry and pharmaceutical industry. With beautiful appearance, anti-skid stair treads are ideal for stairs and platform.

Application of anti-skid stair steps:

- As anti-skid treads of stairs, bridge walkway, train ladder, etc.

- For production workshop, dock to ensure operation safety.

- Drain ice, snow, mud stains in traffic facilities.

We offer four types of anti-skid stair steps as the following:

- Diamond Safety Grating Stair Treads.

- Perforated anti-skid stair treads with round holes.

- Perforated large round hole stair treads.

- Interlock safety grating stair treads.

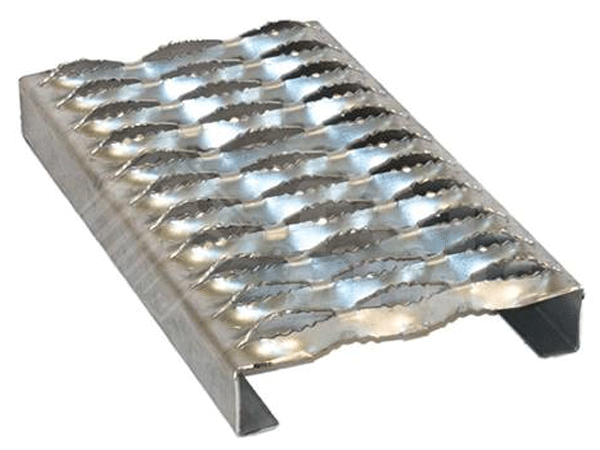

Diamond Safety Grating Stair Treads

Diamond anti-skid safety plate is widely applied to the indoor and outdoor stairs treads of industrial factory, walkway, workshop, traffic facilities, etc. And when the mud stains, ice, snow attached to the floor, the anti-skid stair treads can ensure the safety of staff effectively.

Features of diamond safety grating stair treads:

- High pressure resistance and skid resistance.

- Drain ice, snow, mud stains, grease to ensure workers safety.

- Good load capacity.

- Beautiful appearance.

- Long service life.

Specification for Diamond Safety Grating Stair Treads

| Material | Span inches | Gauge | Depth | Standard stair treads | Stair treads with nosing |

| Steel | Up to 30 | 14 or 12 gauge | 1-1/2″ | 2 Diamonds (4-3/4″) 3 Diamonds (7″) 4 Diamonds (9-1/2″) 5 Diamonds (11-3/4″) |

3 Diamonds (8-1/8″) 4 Diamonds (10-1/2″) |

| 30–36 | 1-1/2″ | ||||

| 36–42 | 1-1/2″ | ||||

| 42–48 | 2″ | ||||

| Aluminium | Up to 42 | 0.080″ | 2″ | ||

| Up to 48 | 0.100″ | ||||

| Stainless steel | Up to 30 | 316L 16 gauge | 2″ | ||

| Up to 36 | 304L 16 gauge |

Perforated anti-skid stair treads with round holes

Features for round hole anti-skid-stair-treads:

- Can self cleaning.

- Easy to maintain.

- Aging resistance and beautiful.

- Good sound-absorbing effect.

| Specification of round hole anti-skid stair treads | ||||

| Material | Thickness (mm) | Length | Width | Height |

| Mild steel | 2.0, 2.5, 3.0 | 6000 mm | 120 mm 150 mm 180 mm 210 mm 240 mm 270 mm |

40 mm 50 mm 75 mm |

| Hot-galvanized or pre-galvanized | 2.0, 2.5, 3.0 | |||

| Stainless steel | 2.0, 2.5 | |||

| Aluminum ENAW 5754 | 2.0, 2.5, 3.0 | |||

Perforated large round hole stair treads

Features of perforated large round hole stair treads:

- Large holes keep the surface enough dry.

- Galvanized surface is anti-rust.

- Light and simple structure are convenient.

| Specification of perforated large round hole stair treads | ||||

| Diamond Pattern | Width | Channel Depth | Pre-galvanized | Weight lb/ft. |

| 13 Holes | 24″ | 5″ | 11 and 13 gauge. | 11.8 |

| 16 Holes | 30″ | 5″ | 11 and 13 gauge | 13.6 |

| 16 Holes | 36″ | 5″ | 11 and 13 gauge | 15.9 |

| Materials: pre-galvanized steel 11 and 13 gauge. | ||||

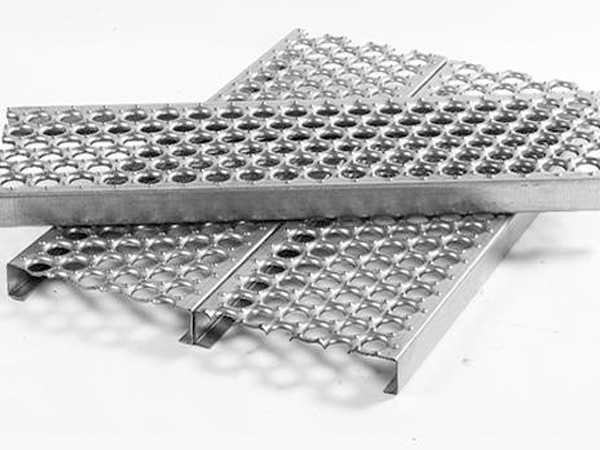

Interlock safety grating stair treads

Features for interlock safety grating stair treads:

- Stable structure.

- Non-corrosive.

- With nosing.

- Long service life.

| Interlock safety grating stair treads sizes | |

| Material | carbon steel, hot dipped mill-galvanized steel |

| Surface treatment | mill galvanized before fabrication |

| Gauge | 14 gauge, 18 gauge or 16 gauge (special) |

| Span length | 24″, 30″, 36″, 48″ |

| Standard Width | 12″, 9″, 6″, 7-1/2″ |

| Width with nosing | 7-1/2″, 10 1/2″, 13-1/2″ |

| Height | 2-1/2″ |

| Surface | MG-traction grip |